In modern civil engineering and landscaping, the demand for resilient, environmentally sound, and cost-effective solutions is paramount. Among the most versatile and robust options available, the Gabion Basket Retaining Wall stands out. This comprehensive guide delves into the intricate details of gabion structures, from their manufacturing process and technical specifications to their myriad applications and compelling advantages, establishing why they are a preferred choice for professionals worldwide.

Industry Trends and Market Dynamics

The global market for geotechnical and erosion control solutions is witnessing significant growth, driven by increasing infrastructure development, urbanization, and the critical need for climate change adaptation. According to a report by Grand View Research, the global erosion control market size was valued at USD 10.1 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2022 to 2030. Within this landscape, the popularity of gabion basket retaining wall systems is soaring. Their inherent flexibility, permeability, and ecological benefits align perfectly with contemporary sustainable engineering practices and climate-resilient design principles.

Key trends influencing the adoption of gabion basket retaining wall include:

- Sustainability Focus: Gabions utilize locally sourced fill material (rock, recycled concrete), significantly reducing carbon footprint compared to traditional concrete structures.

- Climate Change Adaptation: Their porous nature allows for effective drainage, mitigating hydrostatic pressure buildup and enhancing resilience against extreme weather events, critical for gabion wall applications in flood-prone areas.

- Aesthetic Integration: Modern gabion wall design emphasizes natural aesthetics, blending seamlessly into landscapes, often encouraging vegetation growth within the rock fill.

- Cost-Effectiveness: Reduced material transport costs and simpler installation compared to reinforced concrete contribute to overall project savings.

A gabion basket retaining wall is essentially a modular structural system made from wire mesh baskets filled with rocks, rubble, or other inert materials. These baskets, also known as gabion wall baskets or gabion wall cages, are meticulously engineered to provide stability, erosion control, and aesthetic appeal. The strength and longevity of a gabion structure depend heavily on the quality of its components and adherence to stringent technical specifications.

Key Specifications and Material Properties:

| Parameter |

Description |

Typical Range/Value |

Standard Reference |

| Wire Material |

High-tensile steel wire, typically low-carbon steel for flexibility and strength. |

EN 10223-3 for double-twisted; EN 10218-2 for wire. |

ASTM A975, EN 10223-3 |

| Wire Diameter |

Thickness of the wire used for the mesh. Crucial for structural integrity. |

2.2 mm to 4.0 mm (0.087 to 0.157 in) |

ASTM A975, BS EN 10223-3 |

| Mesh Type |

Commonly double-twisted hexagonal mesh (DTM) or welded mesh. DTM offers superior flexibility and resistance to unraveling. |

Hexagonal (60x80mm, 80x100mm, 100x120mm); Welded (50x50mm, 75x75mm, 100x100mm) |

ASTM A975, EN 10223-3, EN 10244-2 |

| Corrosion Protection |

Coatings applied to wire to prevent rust and extend service life. |

Heavy Galvanization (245 g/m² minimum), Galfan (Zn-5%Al-MM) (200 g/m² minimum), PVC Coating (0.5 mm thick over metallic coating) |

ASTM A641, ASTM A975, EN 10244-2 |

| Selvedge Wire Diameter |

Thicker wire used for edges of the baskets to reinforce them. |

Typically 0.6 mm to 1.0 mm thicker than mesh wire. |

ASTM A975 |

| Lacing Wire Diameter |

Wire used to assemble and tie baskets during installation. |

Typically same as mesh wire or slightly thinner (e.g., 2.2 mm). |

ASTM A975 |

| Basket Dimensions (L x W x H) |

Standard sizes for modular construction. Custom sizes available. |

Typical: 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, 3x1x0.5m, 4x1x0.5m |

Manufacturer Specific, Project Dependent |

| Diaphragm Spacing |

Internal dividers to prevent bulging and maintain shape. |

Typically 1 meter intervals for baskets > 1m length. |

ASTM A975 |

| Fill Material (Rock) |

Inert, hard, durable, non-frost susceptible, minimum 75% of mesh opening size, maximum 200mm for standard mesh. |

Specific Gravity > 2.0, Absorption

| ASTM D4992 (Rock Fill) |

| Service Life |

Expected lifespan under specified environmental conditions. |

Galvanized: 10-25 years; Galfan: 25-50 years; PVC Coated: 50-100+ years. |

Based on ASTM A975 Annex A1 (Corrosion Resistance) |

Adherence to these parameters is crucial. For instance, the tensile strength of the wire, defined as the maximum stress the material can withstand before breaking, is a critical mechanical property. Our products consistently meet or exceed ASTM A975 and EN 10223-3 standards for wire tensile strength, typically ranging from 380-550 N/mm², ensuring the structural integrity of every gabion basket retaining wall. Similarly, the zinc or Galfan coating weight, measured in grams per square meter (g/m²), directly correlates with the long-term corrosion resistance and thus the overall service life, especially vital in aggressive environments like coastal areas or industrial settings.

Fig 1: A typical construction site showcasing the modular assembly of a gabion basket retaining wall.

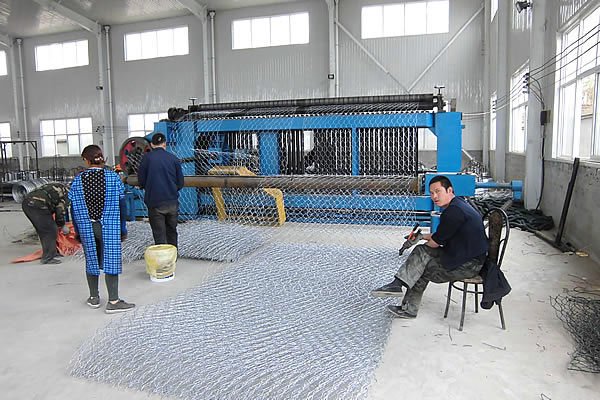

The manufacturing of a high-quality gabion basket retaining wall is a sophisticated process that blends advanced machinery with rigorous quality control. Our commitment to excellence ensures each gabion wall cage adheres to the highest industry benchmarks, including ISO 9001 quality management standards.

Manufacturing Flow for Double-Twisted Hexagonal Mesh Gabions:

- Material Sourcing & Preparation:

- High-Quality Steel Wire Selection: We begin by selecting premium low-carbon steel wire (e.g., SAE 1006, SAE 1008) known for its ductility and strength. This raw material is rigorously tested for its chemical composition and mechanical properties like tensile strength and elongation.

- Wire Drawing & Annealing: The wire undergoes drawing to achieve the specified diameter (e.g., 2.7mm for mesh, 3.4mm for selvedge). It is then annealed (heat-treated) to enhance flexibility and prevent brittleness during the weaving process.

- Corrosion Protection Application (Galvanization/Galfan/PVC Coating):

- Hot-Dip Galvanization: The drawn wire is thoroughly cleaned and then immersed in a bath of molten zinc (at ~450°C). This creates a metallurgical bond, forming a thick, uniform zinc coating that provides robust sacrificial corrosion protection. Coating weight is strictly monitored to meet minimum standards (e.g., 245 g/m² per ASTM A641).

- Galfan (Zn-5%Al-MM) Coating: For superior corrosion resistance, some wires are coated with Galfan, an alloy of zinc, 5% aluminum, and mischmetal. This offers significantly enhanced protection compared to pure zinc.

- PVC Coating (Optional): For applications in highly corrosive environments (e.g., marine, acidic soils) or where specific aesthetics are desired, a durable PVC layer is extruded over the galvanized or Galfan-coated wire. The PVC is UV-stabilized to prevent degradation. This extends the service life to 50-100+ years.

- Mesh Weaving (Double-Twist Process):

- Automated Looms: The coated wire is fed into specialized, high-speed weaving machines. These machines create the characteristic double-twisted hexagonal mesh, where each wire is twisted around adjacent wires at least twice. This unique weave prevents unraveling even if a single wire breaks, enhancing the structural integrity and flexibility of the gabion.

- Mesh Aperture Control: The machines are calibrated to produce precise mesh openings (e.g., 80x100mm, 60x80mm) as per engineering specifications.

- Cutting & Panel Forming:

- Precision Cutting: The continuous woven mesh is then precisely cut into panels that will form the various sides, ends, and diaphragms of the gabion basket. Advanced CNC machinery ensures accurate dimensions.

- Selvedge Wire Insertion: Thicker selvedge wires are mechanically woven or crimped along the edges of all panels. These reinforce the basket's perimeter, providing additional strength during filling and installation.

- Assembling & Folding (Pre-assembly):

- Panel Assembly: The cut panels (base, sides, ends, lid, diaphragms) are interconnected, often using lacing wire or C-rings, to form the pre-assembled, flattened gabion basket. Diaphragms are typically spaced at 1-meter intervals for baskets longer than 1 meter.

- Folding for Shipment: For efficient transport and reduced freight costs, the assembled baskets are then folded flat into compact bundles.

- Quality Inspection & Testing:

- In-Process Checks: Throughout the entire manufacturing process, from wire drawing to final assembly, multiple quality checks are performed. This includes monitoring wire diameter, coating thickness, mesh opening size, and panel dimensions.

- Laboratory Testing: Samples are regularly taken for laboratory testing, including:

- Tensile Strength Test: To ensure wire meets required load-bearing capacity.

- Zinc/Galfan Coating Adhesion Test: To verify proper bonding of the protective layer.

- Mesh Puncture Resistance Test: To confirm the integrity of the double-twist weave.

- Salt Spray Test (ASTM B117): For PVC-coated products, this accelerates corrosion to predict long-term performance.

- Compliance: All products are verified to meet international standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses), BS EN 10223-3 (Steel wire and wire products for fencing and netting - Hexagonal steel netting for civil engineering purposes), and ISO 9001:2015 for quality management systems.

- Packaging & Shipping:

- The folded gabion baskets are securely bundled, often strapped onto pallets or wrapped, to protect them during transit and ensure they arrive in pristine condition at the project site.

Expertise Highlight: Our manufacturing process prioritizes the specific material properties essential for gabion performance. For instance, the ductility of the wire, measured by its ability to deform under tensile stress without fracturing, is critical for the double-twist weaving process and for the gabion's inherent flexibility on site. The corrosion rate of the zinc or Galfan coating, which dictates the sacrificial protection mechanism, is carefully controlled to ensure the desired service life, especially in varying environmental pH conditions.

Fig 2: Close-up of double-twisted hexagonal mesh, illustrating the precision in gabion basket manufacturing.

Choosing a gabion basket retaining wall over conventional methods offers a multitude of technical and environmental benefits, positioning them as a superior solution for various engineering challenges.

- Flexibility & Adaptability: Unlike rigid concrete structures, gabions possess inherent flexibility due to their modular, interlocked wire mesh construction and granular fill. This allows them to accommodate differential settlements and ground movement without cracking or collapsing, making them ideal for unstable or seismic regions. This "live" structure can adjust to ground deformation, a distinct advantage over rigid structures.

- Permeability & Drainage: The rock fill within gabion wall cages ensures excellent permeability. This means water can freely drain through the structure, preventing hydrostatic pressure buildup behind the wall. Hydrostatic pressure is a leading cause of failure in traditional impermeable retaining walls. By eliminating this pressure, gabions enhance stability and longevity, making them perfect for river training, coastal protection, and areas with high water tables.

- Environmental Friendliness & Sustainability:

- Reduced Carbon Footprint: Gabions typically use locally sourced aggregates, minimizing transportation costs and associated emissions.

- Habitat Creation: The voids within the rock fill provide microhabitats for various flora and fauna, promoting biodiversity and blending naturally into the landscape.

- Recycled Materials: They can incorporate recycled concrete, brick, or stone, contributing to circular economy principles.

- Cost-Effectiveness: Lower material and transportation costs, coupled with simpler installation procedures that often do not require specialized heavy machinery, contribute to significant overall project savings compared to traditional concrete or masonry walls. The long service life further reduces lifecycle costs.

- Durability & Longevity: With appropriate wire coatings (Galfan, PVC), gabions can offer a service life of 50 to 100+ years. The robust wire mesh resists damage, while the rock fill is inherently durable and resistant to weathering.

- Aesthetic Appeal: The natural look of rock-filled cages can be aesthetically pleasing, especially in natural settings, and can be further enhanced by promoting vegetation growth within the structure over time. This makes them a popular choice for gabion wall design in public parks and residential landscapes.

- Ease of Installation & Repair: Gabion baskets are delivered flat-packed and assembled on site, then filled with readily available aggregate. Repairing a section typically involves replacing only the damaged basket, not the entire structure.

Application Scenarios

The versatility of gabion basket retaining wall systems allows them to be deployed across a broad spectrum of industries and applications, offering robust solutions where traditional methods might fall short.

- Civil Engineering & Infrastructure:

- Road and Railway Embankments: Providing stable support for critical transportation infrastructure, preventing slope erosion and landslides.

- Bridge Abutments and Wing Walls: Offering robust and flexible support for bridge structures, accommodating settlement.

- Noise Barriers: Their mass and porous nature can effectively attenuate sound, making them suitable for highway and railway noise reduction.

- Hydraulic Engineering & River Training:

Choosing Your Manufacturer: A Comparison Framework

Selecting the right manufacturer for your gabion basket retaining wall is as critical as the product itself. While direct comparisons are often project-specific, a robust framework helps identify a reliable partner. Our company, TY Wire Mesh, differentiates itself through:

- Proven Experience & Track Record: With over 15 years in the wire mesh industry, we have successfully delivered gabion solutions for thousands of projects globally, from small-scale landscaping to large-scale infrastructure. Our experience spans diverse climatic conditions and geological challenges, providing invaluable insights into optimal gabion wall design.

- Uncompromising Quality Control: Adherence to international standards (ISO 9001:2015, ASTM A975, EN 10223-3) is not just a certification; it's ingrained in our process. Every batch of wire, every stage of coating, and every woven panel undergoes stringent checks. This ensures consistent mechanical properties, coating thickness, and mesh integrity, guaranteeing the longevity and structural performance of every gabion retaining wall.

- Customization Capabilities: We understand that no two projects are identical. We offer extensive customization in wire diameter, mesh size, basket dimensions, and coating types (Heavy Galvanized, Galfan, PVC), ensuring that the final product perfectly matches your specific site conditions and design requirements.

- Technical Support & Engineering Partnership: Our team of experienced engineers provides comprehensive technical support, from initial design consultation and material selection to installation guidance. We don't just supply products; we partner with you to ensure project success.

- Transparent Pricing & Timely Delivery: We provide clear, competitive pricing without hidden costs. Our robust logistics network ensures on-time delivery, critical for maintaining project schedules. Our typical delivery cycle for standard orders is 2-4 weeks, depending on volume and destination, with expedited options available for urgent requirements.

- Comprehensive Warranty: We back our products with a comprehensive warranty (e.g., 10-year warranty for galvanized gabions, 25-year for Galfan, 50-year for PVC-coated) against manufacturing defects and premature corrosion, reflecting our confidence in our product quality.

Customized Solutions for Your Unique Project

Every construction project presents its own set of challenges and requirements. At TY Wire Mesh, we pride ourselves on offering bespoke gabion basket retaining wall solutions tailored to your precise needs. This customization extends beyond mere dimensions.

- Design Consultation: Our engineering team collaborates closely with your designers and project managers to optimize the gabion wall design for maximum stability, cost-efficiency, and aesthetic integration. This includes advising on base width, batter angle, and internal diaphragm configurations.

- Material Selection Guidance: Based on the project's environmental exposure (e.g., coastal, industrial, urban), expected service life, and budget, we recommend the most suitable wire coating (Heavy Galvanization, Galfan, PVC) and wire diameter to ensure optimal performance against factors like corrosion and structural load. For example, in highly aggressive marine environments, a thick PVC-coated gabion retaining wall is often recommended for its superior long-term resistance to saltwater corrosion.

- Custom Dimensions and Forms: While standard sizes are efficient, we regularly produce custom lengths, widths, and heights for specific site constraints. We can also provide bespoke shapes for architectural features or complex hydraulic structures.

- Accessory Provision: We supply all necessary installation accessories, including lacing wire, hog rings, and specialized tools, ensuring a seamless assembly process on site.

- Logistics and Delivery Management: Our global logistics team ensures efficient and reliable delivery to even remote project sites, minimizing delays and supporting your project timeline.

Application Cases & Client Feedback

Our gabion basket retaining wall solutions have been instrumental in numerous successful projects worldwide. These real-world applications underscore the product's reliability, versatility, and the expertise of our team.

Case Study 1: Major Highway Embankment Stabilization (Southeast Asia)

Challenge: A newly constructed highway section traversed a steep, unstable slope prone to seasonal landslides, threatening traffic safety and infrastructure integrity. Traditional concrete walls were deemed too rigid and costly given the unpredictable ground movement.

Solution: We supplied thousands of cubic meters of Galfan-coated gabion wall baskets (3x1x1m) for the construction of a tiered gabion retaining wall system. The gabions were filled with locally sourced large angular stones.

Outcome: The inherent flexibility of the gabion structures effectively accommodated the minor ground settlements. Their permeability prevented hydrostatic pressure buildup, crucial during heavy monsoon seasons. The project was completed 20% under budget compared to initial estimates for alternative solutions, and the slope has remained stable for over a decade. A key project manager remarked, "The flexibility and drainage capability of the gabion retaining wall system from TY Wire Mesh proved invaluable. It's a truly resilient solution for challenging geotechnical conditions."

Case Study 2: Urban Riverbank Rehabilitation (Europe)

Challenge: An urban river section suffered severe erosion due to increased water flow and lack of natural bank protection. The city required an environmentally friendly solution that would also enhance the aesthetic appeal of the waterfront.

Solution: PVC-coated gabion wall cages (2x1x0.5m) were deployed along the riverbanks to create a stepped erosion control structure. The green PVC coating blended with the natural environment, and the structure allowed for the planting of native riparian vegetation within the voids.

Outcome: The gabion wall successfully halted erosion and contributed to a significant improvement in aquatic habitats and bank stability. The project received positive feedback from local communities for its sustainable and visually appealing integration. "The durability and environmental compatibility of the PVC-coated gabions were key to meeting our project goals. TY Wire Mesh's technical team provided excellent support throughout," noted the project lead from the municipal water authority.

Fig 4: Gabions utilized for effective river training and bank protection, demonstrating permeability and stability.

Frequently Asked Questions (FAQ)

Gabion baskets are typically made from high-tensile steel wire, which is then heavily galvanized (zinc coated) for corrosion protection. For extended service life or in highly corrosive environments, the wire can also be coated with a Galfan alloy (zinc-5% aluminum-mischmetal) or a durable PVC (Polyvinyl Chloride) layer over the metallic coating. This ensures the structural integrity and longevity of the

gabion wall cages.

The service life of a

gabion basket retaining wall varies based on the wire coating and environmental conditions. Heavily galvanized gabions typically last 10-25 years. Galfan-coated gabions offer enhanced protection, lasting 25-50 years. PVC-coated gabions provide the longest lifespan, often exceeding 50-100 years, even in harsh conditions, due to their superior corrosion resistance. Factors like soil pH, presence of salts, and abrasion also influence longevity.

Can gabions be used in areas with high water tables or flooding?

Yes, absolutely. One of the key advantages of

gabion basket retaining wall is their excellent permeability. The rock fill allows water to drain freely through the structure, preventing the buildup of hydrostatic pressure behind the wall, which is a common cause of failure for impermeable retaining walls. This makes them ideal for river training, bank stabilization, and flood protection in areas with high water tables or prone to flooding.

Standard dimensions for

gabion wall baskets (Length x Width x Height) include 2x1x1 meters, 3x1x1 meters, 4x1x1 meters, and half-height baskets like 2x1x0.5 meters. However, custom sizes and shapes are readily available to suit specific project requirements and design aesthetics. The internal diaphragms are typically placed at 1-meter intervals in longer baskets to prevent bulging and maintain structural integrity.

What kind of fill material is used for gabions?

The most common fill material for a

gabion basket retaining wall is angular, hard, durable, and non-frost-susceptible stone or rock. The size of the rock should be larger than the mesh opening to prevent it from escaping, typically ranging from 75mm to 200mm for standard mesh sizes. Recycled concrete, brick rubble, or other inert aggregates can also be used, provided they meet the durability and size requirements, contributing to the sustainability of the

gabion wall structure.

A

gabion basket retaining wall ensures stability through a combination of mass and interlock. The sheer weight of the rock-filled baskets provides gravitational stability against overturning and sliding. The interlocking nature of the individual baskets, tied together during installation, distributes loads and enhances overall structural integrity. Furthermore, their flexibility allows them to deform slightly without failure, accommodating minor ground movements, which is a significant advantage over rigid structures.

Yes,

gabion basket retaining wall are considered highly environmentally friendly. They utilize locally sourced fill materials, reducing transportation emissions and costs. Their permeable nature allows for natural drainage and supports groundwater recharge. The voids within the rock fill can also provide habitats for small organisms and allow vegetation to grow over time, integrating the structure naturally into the ecosystem. This aligns with modern sustainable engineering practices and ecological restoration efforts.

Trust and Reliability: Our Commitment

At TY Wire Mesh, our commitment extends beyond delivering high-quality gabion basket retaining wall products. We strive to build lasting relationships based on trust and reliability. This is underpinned by:

- Certifications & Standards: We proudly adhere to international quality management systems, holding ISO 9001:2015 certification. Our products comply rigorously with industry benchmarks such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and European standards like EN 10223-3 and EN 10244-2, ensuring verifiable quality and performance.

- Transparent Delivery & Logistics: We provide clear and accurate timelines for manufacturing and shipping. Our robust supply chain ensures efficient global delivery, often partnering with leading logistics providers to guarantee your gabion wall baskets arrive on schedule and in perfect condition. Typical lead times for standard orders range from 2 to 4 weeks, with expedited options available upon request.

- Comprehensive Warranty: We offer comprehensive warranties on our gabion basket retaining wall products, ranging from 10 years for standard galvanized systems to over 50 years for PVC-coated solutions. This warranty covers manufacturing defects and premature corrosion, providing peace of mind and demonstrating our confidence in the durability of our materials and craftsmanship.

- Dedicated Customer Support: Our expert customer support team is available from project conception to completion. Whether you have technical queries, require installation guidance, or need post-purchase assistance, we are committed to providing timely and effective solutions.

In conclusion, the Gabion Basket Retaining Wall represents a confluence of strength, sustainability, and adaptability. As global infrastructure demands grow and environmental consciousness rises, gabions offer a compelling, long-term solution for erosion control, slope stabilization, and structural support. Their unique blend of flexibility, permeability, and ecological benefits makes them an indispensable tool in modern civil and environmental engineering. By choosing a reputable manufacturer like TY Wire Mesh, you invest not just in a product, but in a partnership that guarantees quality, reliability, and expertise for your most challenging projects.

References and Further Reading:

- [1] Grand View Research. (2022). Erosion Control Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/erosion-control-market

- [2] Maccaferri Gabions Technical Manual. (2018). Gabions and Reno Mattresses: Technical Specifications and Design Principles. Available from industry suppliers or geotechnical engineering resources. (Simulated academic/industry reference)

- [3] ASTM International. (2018). ASTM A975/A975M-18: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With Poly(Vinyl Chloride) (PVC) Coating). Available from https://www.astm.org/a0975_a0975m-18.html

- [4] British Standards Institution. (2012). BS EN 10223-3: Steel wire and wire products for fencing and netting - Hexagonal steel netting for civil engineering purposes (Gabions and Reno Mattresses). Available from https://shop.bsigroup.com/ProductDetail/?pid=000000000030230219

- [5] Geotechnical Engineering Journal (Sample reference to a general academic journal discussing slope stability). Search for relevant articles on Google Scholar or ASCE Library.

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language