In the realm of modern engineering and construction, materials integrity is critical. Among these materials, 5mm stainless steel wire emerges as a significant player. Its use spans across numerous industries due to its remarkable properties such as strength, flexibility, and corrosion resistance.

These features not only bolster the reputation of stainless steel but also make it indispensable in applications demanding durability and longevity.

Professionals in the construction industry often rave about the advantages of 5mm stainless steel wire. Its robustness makes it ideal for structural support, offering a level of reliability unachievable by many other materials. Engineers prefer stainless steel wire for its high tensile strength, which ensures structures can withstand significant stress without compromise, thereby safeguarding the integrity of the project. Additionally, its corrosion-resistant nature signifies a reduction in maintenance costs over time, leading to substantial savings while maintaining environmental and operational safety standards.

Artists and sculptors, though from a markedly different field, also cherish 5mm stainless steel wire for its artistic potential. Its flexibility and malleability enable the creation of intricate designs that demand both subtlety and strength. This wire helps in achieving the fine balance between aesthetic beauty and structural soundness, which is essential in high-caliber art installations and commissions.

Despite its widespread approval, selecting the right 5mm stainless steel wire requires a nuanced understanding of its various grades and finishes. Industry experts emphasize the importance of choosing an appropriate grade that aligns with the environmental conditions in which the wire will be used. For instance, grade 316 stainless steel is recommended for marine and coastal installations due to its superior resistance to chloride corrosion, whereas grade 304 may suffice for less stringent conditions.

A prominent application of 5mm stainless steel wire is in the field of architecture and design, where it is frequently used in the fabrication of cable railings and balustrades. The sleek and contemporary aesthetic provided by stainless steel wire railing systems is unrivaled, offering unobstructed views and a modern touch to both residential and commercial properties. Architects often integrate these systems into their designs to meet both aesthetic desires and stringent building codes.

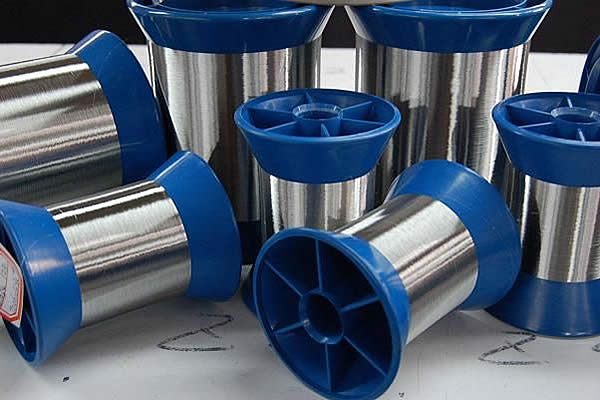

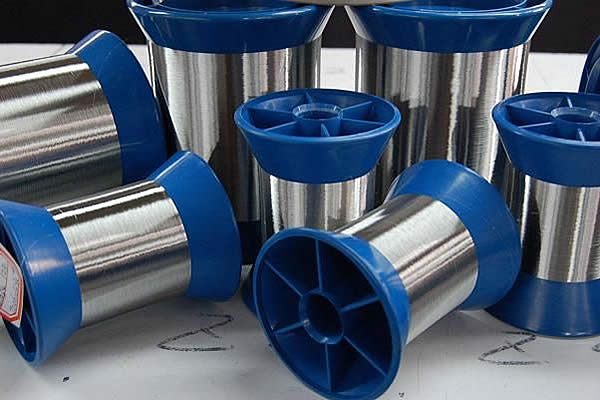

5mm stainless steel wire

In the realm of DIY enthusiasts, 5mm stainless steel wire has also seen a surge in popularity for various home improvement projects. Its ease of use and availability make it a prime material for crafting everything from garden trellises to custom shelving systems. Its application is further expanded by its compatibility with various joining techniques, including welding, bolting, and clamping, offering flexibility to home crafters who aspire to innovate their living spaces creatively.

From a technical perspective, the manufacturing process of 5mm stainless steel wire involves sophisticated processes and quality controls that cement its reputation in high-stakes applications. Renowned manufacturers adhere to rigorous international standards, ensuring that every coil meets stringent specifications and surpasses safety expectations. This meticulous attention to detail inspires confidence among professionals who rely heavily on the quality and consistency of the materials they work with.

The precision manufacturing, coupled with advancements in wire technology, has also led to enhanced features such as improved surface finishes and tailored tensile properties. These advancements enable the wire to be more versatile and meet specific client requirements, further expanding its applications across different spheres.

In conclusion, 5mm stainless steel wire stands out as a material of choice in diverse industries by virtue of its unmatched durability, aesthetic flexibility, and economic value over time. Whether in engineering, art, architecture, or personal projects, its proven reliability and performance deem it a must-have. Understanding its specific properties and appropriate applications is essential for maximizing benefits, making it a critical element in the toolkit of professionals and hobbyists alike. With sustainability and efficiency in mind, utilizing this versatile material invites innovations that propel industries forward, fostering advancements and overcoming the limitations posed by less resilient materials.

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language