TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

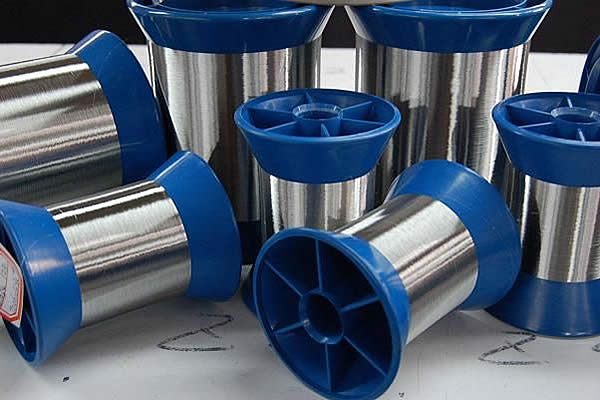

Understanding 304 Stainless Steel Wire Properties, Applications, and Benefits

Stainless steel is celebrated for its exceptional resistance to corrosion, strength, and versatility, making it a popular choice across various industries. Among its many grades, 304 stainless steel stands out as one of the most widely used types due to its remarkable properties and a range of applications, including the production of stainless steel wire.

Composition and Properties of 304 Stainless Steel

304 stainless steel is part of the austenitic family of stainless steels, which are known for their high chromium and nickel content. The typical composition of 304 stainless steel includes approximately 18% chromium and 8% nickel, which endow it with excellent corrosion resistance and good formability. This alloy is non-magnetic and can be easily welded and fabricated, making it particularly suitable for numerous applications.

One of the key features of 304 stainless steel is its high resistance to oxidation and scaling, which is a common issue in high-temperature environments. This ensures that items made from 304 stainless steel maintain their structural integrity, even when exposed to harsh conditions. Furthermore, the alloy's ability to withstand both acidic and alkaline environments enhances its appeal in various industrial sectors.

Applications of 304 Stainless Steel Wire

304 stainless steel wire is utilized in an array of applications across different fields. Some common uses include

1. Industrial Applications Due to its durability and resistance to corrosion, 304 stainless steel wire is often used in the manufacturing of wire ropes, lifting slings, and safety cables. These products are crucial in construction, maritime, and heavy machinery sectors.

2. Food Processing The stainless steel wire is also commonly found in the food industry, ensuring compliance with health and safety regulations. It's used in applications such as food conveyor belts, screens, and baskets, where hygiene and cleanliness are paramount.

3. Medical Devices In the medical industry, 304 stainless steel wire is used to create instruments and devices due to its non-reactive properties. Surgical tools, implants, and other medical applications benefit from the material's strength and resistance to sterilization processes.

4. Construction and Architecture 304 stainless steel wire can be employed in architectural applications like cable railings, tension systems, and decorative designs. Its aesthetic appeal combined with durability makes it a favorite among architects and designers.

5. Automotive Industry In the automotive sector, 304 stainless steel wire is used in the production of various components, including springs, exhaust systems, and other parts that require high strength and resistance to wear and corrosion.

Advantages of Using 304 Stainless Steel Wire

The advantages of 304 stainless steel wire are significant. Firstly, its resistance to corrosion helps prolong the life of products, minimizing maintenance and replacement costs. Secondly, its strength allows it to be used in critical applications where security and reliability are essential. Additionally, the versatility of 304 stainless steel wire means it can be easily manufactured into different shapes and sizes to meet specific requirements.

Moreover, 304 stainless steel is recyclable, making it an environmentally friendly option in an era where sustainability is paramount. This contributes to reducing the carbon footprint of manufacturing processes and supports a circular economy.

Conclusion

In summary, 304 stainless steel wire is an essential component in various industries due to its unique properties and versatility. Its exceptional resistance to corrosion, strength, and aesthetic appeal make it an attractive choice for applications ranging from food processing to medical devices and architecture. By choosing 304 stainless steel wire, manufacturers and designers can ensure durability, reliability, and sustainability in their projects, reflecting the ongoing evolution and advancement in material science. Whether in industrial settings or consumer products, the importance of 304 stainless steel wire cannot be overstated.