TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

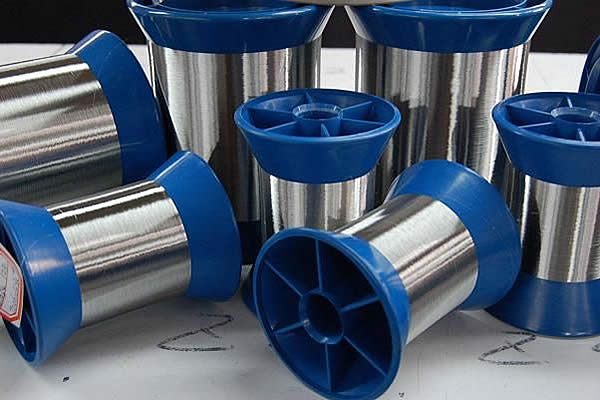

Understanding Electro Galvanized Iron Wire Features and Applications

Electro galvanized iron wire has become increasingly popular in various industries due to its excellent corrosion resistance, strength, and versatility. This specialized product is produced by a process known as electro-galvanization, where a layer of zinc is deposited onto the iron wire through an electrochemical process. This article will delve into the characteristics, manufacturing process, and applications of electro galvanized iron wire.

Characteristics of Electro Galvanized Iron Wire

One of the most significant features of electro galvanized iron wire is its superior resistance to rust and corrosion. The thin layer of zinc provides a protective barrier that prevents moisture and oxygen from reaching the underlying iron, which can lead to oxidation and degradation over time. This makes electro galvanized iron wire ideal for applications in areas with high humidity or exposure to chemicals.

The wire's steel core ensures high tensile strength, making it suitable for various applications, including construction and fencing. Another important characteristic is the smooth surface finish that electro galvanization provides. This characteristic is not only aesthetically pleasing but also reduces friction, making the wire easier to handle and work with during installation.

Manufacturing Process

The manufacturing of electro galvanized iron wire involves several key steps. It starts with the selection of high-quality iron or steel wire, which is then cleaned using a series of chemical baths to remove any dirt, rust, or grease. Once the wire is thoroughly cleaned, it is immersed in a bath containing zinc, where an electric current is applied. This current causes zinc ions to migrate and bond to the surface of the wire, creating a uniform coating.

After the electro-galvanization process, the wire is rinsed and dried to remove any residual chemicals. Quality control measures are then implemented to ensure that the zinc coating meets specified thickness standards and that the wire maintains its structural integrity. The finished product is then spooled and packaged, ready for distribution to various industries.

Applications of Electro Galvanized Iron Wire

Electro galvanized iron wire finds applications in numerous fields due to its varied properties. One of the primary uses is in construction, where it is used for reinforcing concrete, as binding wire, and for the production of wire meshes. Its corrosion resistance is particularly beneficial in outdoor applications, making it a preferred choice for fences and wire enclosures in gardens, farms, and industrial sites.

In addition to construction, electro galvanized iron wire is commonly used in the manufacturing of various types of products, such as hooks, nails, and brackets. Its strength and durability make it suitable for automotive and electrical applications, including wiring and support structures.

Moreover, electro galvanized iron wire is increasingly being adopted in landscaping and horticulture. It is used to create trellises, plant supports, and rabbit-proof fencing due to its ability to withstand outdoor elements without significant deterioration.

Conclusion

Electro galvanized iron wire is undoubtedly a vital material that plays a crucial role in numerous industries. Its impressive corrosion resistance, strength, and versatility make it a preferred choice in construction, manufacturing, and landscaping. As industries continue to evolve and the demand for durable materials increases, the relevance of electro galvanized iron wire is expected to grow even further. Thus, understanding its properties and applications can help individuals and businesses make informed choices in their respective projects. Whether for construction, crafting, or agricultural uses, electro galvanized iron wire remains an essential component of modern industrial practices.