TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

Types of Iron Mesh

Iron mesh is a versatile and sturdy material commonly used in construction, manufacturing, and various other industries. Its ability to provide structural support, act as a barrier, and enhance aesthetic appeal makes it a popular choice for many applications. In this article, we will explore the different types of iron mesh, their characteristics, and their uses.

1. Welded Wire Mesh

Welded wire mesh is formed by welding together intersecting wires at each junction, creating a strong and stable grid. This type of mesh is widely used in construction for reinforcing concrete structures, fences, and livestock enclosures. Its uniformity in spacing allows for evenly distributed loads, making it a reliable choice for structural applications. Additionally, welded wire mesh is available in various wire diameters and grid sizes, catering to different project requirements.

2. Expanded Metal Mesh

Expanded metal mesh is produced by slitting and stretching a metal sheet to create a pattern of diamond-shaped openings. It is known for its lightweight yet durable nature, making it ideal for applications such as security screens, infill panels, and walkways. The open design of expanded metal allows for ventilation, visibility, and light transmission, which is particularly beneficial in architectural projects and industrial facilities.

3

. Perforated Metal Mesh

Perforated metal mesh is created by punching holes into a solid sheet of metal, resulting in a material that combines structural integrity with aesthetic appeal. This type of mesh is often used in decorative applications, such as facades, screens, and architectural elements. The size, shape, and arrangement of the perforations can be customized to achieve specific design goals, making perforated metal a popular choice among architects and designers.

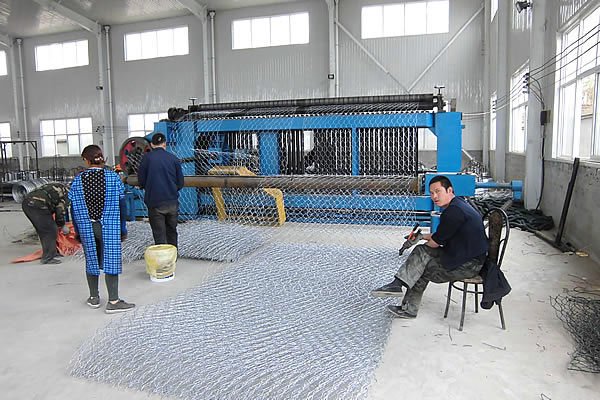

4. Chain Link Mesh

Chain link mesh consists of interwoven steel wires, forming a flexible and cost-effective fencing solution. Commonly used for security fencing around residential, commercial, and industrial properties, chain link mesh provides visibility while effectively deterring intruders. Available in various heights and wire gauges, it can be coated with vinyl or galvanized for added protection against rust and corrosion.

5. Stainless Steel Mesh

Stainless steel mesh combines the strength of iron with the corrosion resistance of stainless steel, making it a superior choice for specialized applications. It is commonly used in environments that require high durability and resistance to harsh chemicals or weather conditions. Applications range from filter screens in industrial settings to safety barriers in public spaces. While it may come at a higher cost than other types of iron mesh, its long-term benefits often justify the investment.

Conclusion

The diverse types of iron mesh serve a wide array of functions across multiple industries. Whether it’s the strength of welded wire mesh, the lightweight nature of expanded metal, the aesthetic flexibility of perforated mesh, the security of chain link, or the durability of stainless steel, each type offers unique properties that cater to specific needs. Understanding these differences can help individuals and businesses select the right type of iron mesh for their projects, ensuring functionality, safety, and style. As industries continue to evolve, we can expect innovations in iron mesh technology that will further enhance its applications and effectiveness.