TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

The Versatility and Significance of Annealed Iron

Annealed iron is a crucial material in various industrial applications, revered for its unique properties and adaptability. Annealing is a heat treatment process that alters a metal’s physical and sometimes chemical properties to increase its ductility and reduce its hardness, making it more workable. This process is particularly significant in the production and treatment of iron, especially for high-carbon variants that can be quite brittle and challenging to work with.

The process of annealing involves heating the iron to a temperature where its structure can reorganize, followed by a slow cooling phase. This slow cooling relieves internal stresses within the metal, which can accumulate during processes like forging or welding. As a result, the annulated iron exhibits improved ductility, making it ideal for manufacturing components that need to undergo shaping or deformation without cracking.

One of the primary benefits of annealed iron is its enhanced machinability. In industries such as automotive, aerospace, and construction, components made from annealed iron can be easily cut, shaped, and welded. This is particularly important in manufacturing processes that require precise tolerances. For example, various automotive parts, from frames to brackets, often utilize annealed iron due to its ability to withstand the demands of high stress and vibration, while still being easy to machine and assemble.

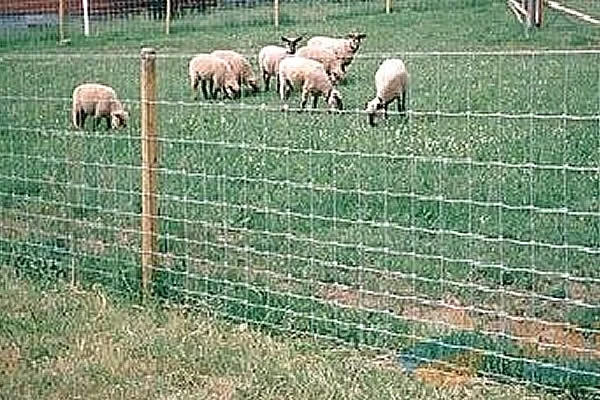

Another notable application of annealed iron is in the production of wire

. Annealed iron wire finds its usage in crafting, fencing, and construction applications. The flexibility of the wire allows it to be bent and formed into various shapes and is critical for applications that require a lot of handling, such as in electrical cabling or in establishing fencing where some degree of tension is necessary.Environmental factors also play a role in the preference for annealed iron. In many cases, the treatment reduces the likelihood of rust formation by creating a more uniform structure that can be treated with protective coatings more effectively. With rising concerns about sustainability and the long-term durability of materials, annealed iron presents an appealing option for manufacturers looking to reduce maintenance costs or enhance the lifespan of products.

Moreover, annealed iron is often used in the construction of heavy machinery and industrial equipment. Its ability to absorb vibration and impact makes it a material of choice for components that are exposed to cyclical loads or significant structural stress. Elements such as gears, shafts, and several parts of major machines benefit from the properties of annealed iron, facilitating smoother operation and longevity.

In conclusion, the significance of annealed iron in modern industry cannot be overstated. Its ability to combine ductility with strength opens up a wide range of applications, from automotive components to industrial machinery. The annealing process not only enhances the material properties of iron but also aligns with modern manufacturing demands for durability, efficiency, and reduced environmental impact. As industries continue to evolve, the role of annealed iron is likely to grow, reinforcing its status as a foundational material in various technological advancements.