TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

In contemporary civil engineering and landscape architecture, the demand for resilient, sustainable, and aesthetically pleasing earth retention solutions continues to escalate. Among the most versatile and eco-friendly options gaining prominence is the gabion basket retaining wall. These robust structures, essentially wire mesh container111s filled with rocks, have transcended their traditional roles in erosion control and are now integral to modern infrastructure projects, urban design, and environmental protection initiatives. The industry is witnessing a significant trend towards integrated natural solutions that minimize environmental impact while maximizing structural integrity and durability. This includes greater emphasis on recycled materials, long-term performance under varied climatic conditions, and adaptability to complex site challenges. As B2B decision-makers and technical professionals evaluate solutions for slope stabilization, hydraulic structures, and architectural landscaping, understanding the intrinsic value and evolving capabilities of gabion structures becomes paramount.

The market for gabion solutions is driven by their cost-effectiveness, permeability, and inherent flexibility, which allows them to withstand ground movement without catastrophic failure—a critical advantage over rigid concrete structures. Innovations in coating technologies and mesh designs are further enhancing their longevity and aesthetic appeal, broadening their application spectrum from industrial sites to public parks and residential developments. This adaptable technology offers a compelling blend of engineering practicality and environmental stewardship, making it a preferred choice for forward-thinking projects worldwide.

The integrity and performance of a gabion wall fundamentally depend on the precision and quality of its manufacturing process. Our gabion baskets are crafted from high-quality steel wire, typically low-carbon steel, which undergoes rigorous processing to meet stringent international standards. The primary material choice, often galvanized steel or PVC-coated galvanized steel, is critical for long-term corrosion resistance. Galvanization involves hot-dipping the steel wire in molten zinc, creating a protective layer that adheres metallurgical to the base steel. For enhanced durability in aggressive environments, an additional PVC coating is applied over the galvanized wire, providing superior protection against chemical and abrasive elements.

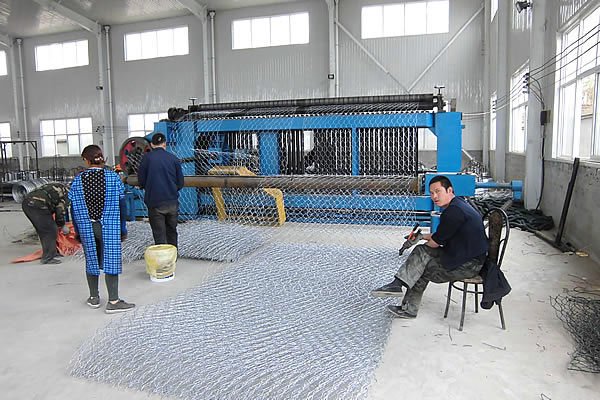

The manufacturing process begins with the selection of wire coils, which are then drawn to the precise diameter required for the specific gabion mesh (e.g., 2.2mm, 2.7mm, 3.0mm, or 4.0mm). These wires are then woven or welded into hexagonal or square mesh patterns, respectively. Hexagonal mesh, formed by a double-twist weaving process, offers exceptional flexibility and prevents unraveling if a wire breaks. Welded mesh gabions, made from resistance-welded wire, provide a more rigid, aesthetically uniform structure often preferred for architectural applications. After the mesh panels are formed, they are cut to size, folded, and often pre-assembled for easier on-site installation. Critical inspection standards, such as ISO 9001 for quality management and ASTM A975/EN 10223-3 for wire and mesh specifications, are adhered to throughout the production cycle, ensuring consistency and reliability. This meticulous approach guarantees a service life often exceeding 50 years, making our gabion retaining wall solutions suitable for diverse sectors including infrastructure development, hydraulic engineering, erosion control, and landscape architecture, offering inherent advantages in drainage, stability, and environmental integration.

Understanding the precise technical parameters of gabion wall baskets is crucial for successful project implementation and long-term performance. Our gabion units are engineered to meet specific design requirements, offering a range of sizes, wire diameters, and coating options to suit various environmental and structural demands. The mesh configuration, typically hexagonal double-twist or square welded mesh, plays a significant role in the basket's structural integrity and ability to contain the rock fill.

| Parameter | Description / Value Range |

|---|---|

| Wire Diameter (Mesh) | 2.0mm - 4.0mm (standard) |

| Wire Diameter (Selvedge) | Often 0.5-1.0mm thicker than mesh wire |

| Mesh Opening Size | 60x80mm, 80x100mm, 100x120mm (Hexagonal) / 50x50mm, 75x75mm, 100x100mm (Welded) |

| Standard Dimensions (L x W x H) | 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m (and custom sizes) |

| Coating Type | Hot-dip Galvanized, Zn-Al Alloy (GalFan/Galfan+), PVC Coated |

| Zinc Coating Weight | Min. 245 g/m² (for 2.7mm wire, ASTM A641/EN 10244-2 Class A) |

| PVC Coating Thickness | Typically 0.4mm - 0.5mm (over galvanized wire) |

| Tensile Strength | 380-550 N/mm² (Wire strength, EN 10223-3) |

| Service Life Expectancy | Galvanized: 25-50 years; PVC Coated: 50-75+ years |

These specifications ensure that a gabion wall can effectively manage water flow, dissipate energy, and resist erosive forces while maintaining structural integrity. The inherent permeability of gabion structures allows for hydrostatic pressure relief, preventing the build-up of water behind the wall and mitigating failure risks common in impermeable structures. Furthermore, the flexibility of gabions allows them to settle and conform to ground movement without cracking, making them ideal for unstable soil conditions or areas prone to seismic activity.

The versatility of the gabion basket retaining wall extends across a broad spectrum of engineering and architectural applications, making it a preferred choice for complex projects where traditional methods fall short. Their robust nature and unique design properties provide significant technical advantages.

These combined benefits underscore why gabion structures are becoming the go-to solution for engineers and designers seeking robust, sustainable, and aesthetically pleasing earth retention systems.

Recognizing that every project presents unique challenges, we specialize in providing highly customized gabion basket retaining wall solutions. Our engineering team works closely with clients to develop designs that perfectly match specific site conditions, aesthetic preferences, and performance requirements. From varying dimensions and mesh types to specialized coatings and fill materials, our capacity for customization ensures optimal functionality and visual integration. We can produce gabion baskets in non-standard lengths, widths, and heights, design specific diaphragm configurations, and recommend the most suitable wire gauge and coating for the intended environment—be it freshwater, saltwater, or highly abrasive industrial settings.

When selecting a manufacturer for your gabion project, several critical factors should influence your decision beyond just initial cost. A reputable supplier should demonstrate a proven track record, adherence to international quality standards, and robust technical support. It is imperative to verify that the manufacturer's products comply with industry benchmarks like ISO 9001 for quality management systems, and relevant material standards such as ASTM A975 (for hexagonal gabion mesh) or EN 10223-3. Furthermore, assessing their capacity for timely delivery, project-specific engineering consultation, and post-sales support, including installation guidance, are essential for a successful partnership. Our commitment to these principles ensures that clients receive not just a product, but a comprehensive, reliable solution for their earth retention needs.

Building trust in the B2B sector for products like the gabion wall design and components hinges on demonstrable quality assurance, transparent processes, and robust customer support. Our commitment begins with strict adherence to internationally recognized standards, including ISO 9001 for our manufacturing processes, guaranteeing consistent product quality. All raw materials are sourced from certified suppliers, and each batch of wire undergoes rigorous testing for tensile strength, zinc coating weight, and other critical parameters to ensure compliance with ASTM A975, EN 10223-3, and other relevant standards. Test certificates are provided upon request, offering complete transparency.

Understanding the critical timelines of large-scale infrastructure projects, we maintain efficient production lines and a streamlined logistics network to ensure reliable delivery cycles. Our standard lead times are competitive, and we offer flexible shipping options to accommodate urgent project requirements, minimizing potential delays on your construction site. Each order is carefully packaged to prevent damage during transit, ensuring that the gabion basket retaining wall components arrive in pristine condition, ready for immediate assembly.

Our dedication extends beyond product delivery to comprehensive customer support. We offer detailed installation guides, technical consultations, and responsive after-sales service to address any queries or challenges that may arise during project execution. Our products come with a substantial warranty, covering material defects and manufacturing faults, underscoring our confidence in the longevity and performance of our gabion solutions. This holistic approach, from initial consultation to long-term performance, solidifies our position as a trusted partner in providing high-quality gabion systems.

The strategic deployment of a gabion basket retaining wall represents a forward-thinking approach to modern engineering challenges. Their inherent flexibility, superior drainage capabilities, environmental compatibility, and long service life position them as an optimal choice for a wide range of applications, from critical infrastructure protection to innovative architectural landscaping. As the industry continues to prioritize sustainable and resilient solutions, the technical advantages and adaptability of gabion systems will only further solidify their indispensable role. Choosing a reputable manufacturer dedicated to stringent quality controls, comprehensive technical support, and tailored solutions is paramount to realizing the full potential of these versatile structures, ensuring both project success and long-term value.