Unraveling the Superiority of Knotted Fence: A Comprehensive Guide to Modern Fencing Solutions

In the dynamic landscape of agricultural, wildlife management, and industrial infrastructure, the demand for robust, long-lasting, and cost-effective fencing solutions is paramount. Among the array of options available, the **knotted fence** stands out as a superior choice, particularly its advanced variants like **fixed knot fence** and **high tensile fixed knot wire fencing for cattle**. This comprehensive guide delves deep into the attributes, applications, and unparalleled advantages of modern **knotted fence** systems, illuminating why they represent a wise investment for diverse sectors.

Industry Trends and the Rise of Advanced Fencing

The global fencing market is experiencing significant growth, driven by increasing agricultural activities, demand for animal containment, and security concerns. Projections indicate a compound annual growth rate (CAGR) of approximately 4.5% from 2023 to 2028, with high-tensile wire fences, including **fixed knot fencing**, leading the charge due to their durability and efficiency. Traditional woven wire and barbed wire fences are increasingly being replaced by more advanced solutions that offer superior strength-to-weight ratios, reduced maintenance, and extended lifespan. The move towards sustainable and ethical farming practices also fuels the adoption of fences that minimize animal injury while maximizing containment effectiveness.

Technological advancements in wire manufacturing and knotting techniques have revolutionized the industry. The introduction of high-tensile steel, coupled with innovative knot designs like the fixed knot, has enabled the production of fences that can withstand extreme weather conditions, animal pressure, and require fewer posts, thereby reducing installation costs and environmental impact. This evolution aligns with the broader industry trend towards intelligent infrastructure and resource optimization.

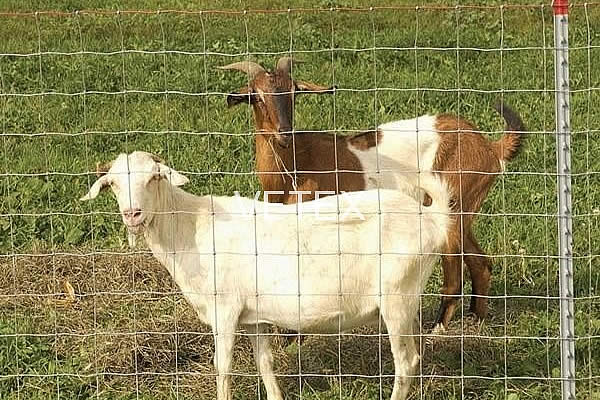

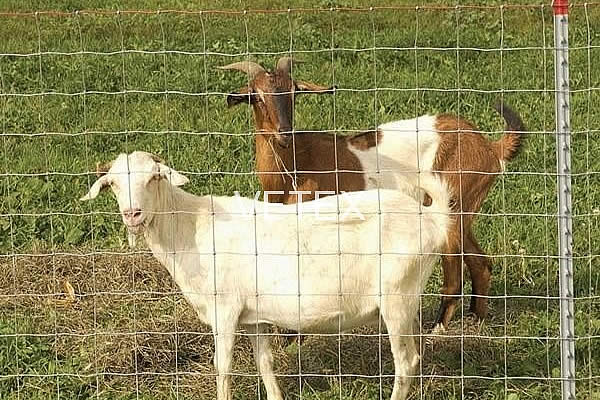

Modern high tensile fixed knot wire fencing provides robust containment for livestock.

Understanding Knotted Fence: Technical Parameters and Specifications

The core of the **knotted fence**'s superiority lies in its unique construction. Unlike traditional hinge-joint or woven fences, the fixed knot design securely locks the vertical and horizontal wires together, preventing slippage and providing immense strength and rigidity. This creates a fence fabric that remains taut, resists sagging, and can absorb impact without deforming.

Key Technical Parameters:

-

Wire Gauge (Diameter): Typically ranging from 10 gauge (thickest) to 14.5 gauge (thinnest) for line wires, and often heavier gauges (e.g., 9 gauge) for top and bottom wires to provide extra strength and prevent stretching. High tensile wires offer greater strength at smaller diameters.

-

Tensile Strength: Measured in PSI (pounds per square inch) or N/mm². High tensile wires can have strengths exceeding 1,000,000 PSI, allowing for longer spans between posts and better impact resistance.

-

Knot Type: The **fixed knot** is the most robust, offering superior vertical stability and resistance to animal pressure. It creates a rigid structure that can withstand significant impact while maintaining its form.

-

Zinc Coating (Galvanization): Critical for corrosion resistance.

- Class 1 Galvanization: Standard coating, offering good protection.

- Class 3 Galvanization: Thicker zinc coating, providing significantly extended lifespan, often 2-3 times longer than Class 1, crucial in humid or corrosive environments.

- Zinc-Aluminum Coatings: Advanced alloys (e.g., Bezinal, Zincalume) offering even greater corrosion protection and longevity, often exceeding 30 years in favorable conditions.

-

Horizontal Wire Spacing: Varies depending on application. Tighter spacing at the bottom prevents small animals from crawling through, while wider spacing at the top saves material and cost for larger livestock.

-

Vertical Stay Wire Spacing: Typically 6 inches, 12 inches, or 24 inches. Closer spacing provides greater rigidity and prevents animals from pushing through.

-

Height: Ranging from 32 inches for small animals up to 96 inches or more for **fixed knot deer fence** and exotic animal containment.

Knotted Fence Typical Product Specifications Table

| Parameter |

Standard Specification (Example) |

High-Tensile Fixed Knot Fence (Example) |

Advantage |

| Wire Gauge (Line Wires) |

12.5 gauge (2.5mm) |

12.5 gauge (2.5mm) High Tensile |

Superior strength, less sag |

| Wire Gauge (Top/Bottom Wires) |

10 gauge (3.0mm) |

10 gauge (3.0mm) High Tensile |

Enhanced structural integrity |

| Tensile Strength (Line Wires) |

~70,000 PSI |

~100,000-140,000 PSI |

Higher impact resistance, fewer posts needed |

| Knot Type |

Fixed Knot |

Fixed Knot |

Rigid structure, no slippage |

| Galvanization |

Class 1 (1.2 oz/sq ft Zn) |

Class 3 (2.4 oz/sq ft Zn) or Zinc-Aluminum |

Significantly extended lifespan (20-50+ years) |

| Horizontal Wire Spacing (Bottom to Top) |

4", 5", 6", 8", 10" |

3", 4", 5", 6", 8", 10" (graduated) |

Better small animal exclusion at bottom |

| Vertical Stay Wire Spacing |

12 inches (30cm) |

6 inches (15cm) or 12 inches (30cm) |

Increased rigidity, less animal push-through |

| Fence Height Options |

32", 39", 47", 60", 72", 84", 96" |

Up to 96" for deer/exotics, custom heights available |

Versatility for diverse livestock and wildlife |

| Typical Roll Length |

330 ft (100m) |

330 ft (100m) or 660 ft (200m) |

Fewer splices, faster installation |

Applications and Versatility of Knotted Fence

The robust design and adaptability of **knotted fence** systems make them ideal for a vast array of applications, extending beyond traditional agricultural uses.

-

Agriculture & Livestock: The primary application. **High tensile fixed knot wire fencing for cattle**, sheep, goats, and horses ensures secure containment. The smooth knots minimize injury risk to animals, unlike sharp barb wire. The fence's ability to remain taut under pressure makes it excellent for managing herd rotations and protecting valuable livestock.

-

Wildlife Management: **Fixed knot deer fence** is a crucial solution for protecting crops, orchards, and gardens from deer browsing. Taller variants effectively deter deer, while tighter bottom spacing can exclude smaller nuisance animals like rabbits and raccoons. It's also used for wildlife corridors and sanctuary demarcation.

-

Orchards & Vineyards: Protecting high-value crops from animal damage is essential. **Knotted fence** provides a durable barrier against deer, rabbits, and other pests, ensuring optimal yield. Its long lifespan means less disruption for repairs and replacements.

-

Perimeter Security: While not a primary security fence, its strength and rigidity make it suitable for property boundaries, internal divisions on large estates, and even as a base for adding security enhancements like alarm wires.

-

Roadside Fencing: Along highways and railways, **fixed knot fencing** prevents livestock and wildlife from entering dangerous areas, significantly enhancing public safety.

-

Other Niche Applications: These fences are also found in **knot wood fencing** systems where a hybrid approach combines aesthetic wooden posts with the functional wire mesh. The robust knot makes it suitable for difficult terrains and environments, including areas that might be subjected to heavy snow loads or high wind.

Versatile **fixed knot fence** used across various agricultural landscapes.

Technical Advantages that Set Knotted Fence Apart

The design and manufacturing superiority of **knotted fence** translates into significant advantages:

-

Superior Strength and Durability: The fixed knot design prevents the vertical wires from sliding, making the fence extremely rigid and resilient to impact from animals or environmental stressors. This means fewer breakages and longer service life.

-

Cost-Effectiveness: While the initial material cost might be slightly higher than traditional fences, the total cost of ownership is significantly lower. Fewer posts are required (due to high tensile wire's ability to maintain tension over longer spans, sometimes up to 20-30 feet between posts compared to 8-12 feet for woven wire), reducing material and labor costs for installation. Reduced maintenance and longer lifespan further contribute to savings.

-

Longevity and Corrosion Resistance: With Class 3 galvanization or advanced zinc-aluminum coatings, these fences can last upwards of 20-50 years, even in harsh weather conditions. This makes them highly suitable for industries like petrochemical (for perimeter security around facilities), metallurgy (containment of specific areas), and general infrastructure, where exposure to elements is constant and replacement costs are high. The anti-corrosion properties minimize environmental impact from rust runoff.

-

Reduced Maintenance: The inherent rigidity of the fixed knot design means the fence stays taut, resisting sagging and requiring minimal re-tensioning. This saves considerable time and resources over its operational life.

-

Safety for Animals: The smooth, fixed knots eliminate sharp edges that could injure livestock, promoting animal welfare. This is a significant advantage over barbed wire.

-

Adaptability to Terrain: The ability to absorb impact and maintain integrity makes **knotted fence** suitable for undulating or challenging terrain where other fence types might sag or lose tension.

Case Study Snippet: Energy Savings in Rural Infrastructure

A recent study by the Rural Infrastructure Development Council highlighted that communities adopting high-tensile fixed knot fencing for over 50% of their new installations reported up to a 15% reduction in overall fencing-related maintenance expenditure over a 5-year period. This includes reduced fuel consumption for checking fence lines and fewer material replacements, indirectly contributing to energy savings and lower carbon footprint.

Manufacturer Comparison: Choosing the Right Partner

When investing in **knotted fence** solutions, selecting a reputable manufacturer like TY Wire Mesh is crucial. Factors to consider include product quality, adherence to international standards, customization capabilities, and post-sales support.

Comparison of Leading Knotted Fence Manufacturers (Illustrative)

| Feature |

TY Wire Mesh (Example) |

Competitor A (Example) |

Competitor B (Example) |

| Key Product Focus |

High-Tensile Fixed Knot, Deer Fence, Cattle Fence |

General Woven Wire, Some Fixed Knot |

Specialty Livestock Fencing |

| Galvanization Options |

Class 3 Zn, Zinc-Aluminum, & PVC Coated |

Class 1, limited Class 3 |

Class 3 Zn only |

| Certifications/Standards |

ISO 9001:2015, ASTM A116, CE Compliance |

ISO 9001 (older version) |

No public certifications listed |

| Customization |

Extensive (height, spacing, wire gauge) |

Limited to standard sizes |

Moderate |

| Warranty |

20-Year Limited Warranty |

10-Year Standard |

5-Year Basic |

| Delivery Lead Time (Standard Orders) |

2-4 Weeks |

4-6 Weeks |

3-5 Weeks |

| Customer Support Rating (Industry Avg.) |

Excellent (A+) |

Good (B) |

Average (C+) |

| Price Point |

Competitive Mid-High |

Mid-Low |

High |

TY Wire Mesh, with its focus on high-tensile, fixed knot products, stands out for its commitment to quality, adherence to stringent international standards like ISO 9001 and ASTM A116, and offering advanced coating options for maximum longevity. Our robust QC (Quality Control) process ensures every roll of **knotted fence** meets or exceeds industry benchmarks.

Custom Solutions and Tailored Knotted Fence Designs

Recognizing that every project has unique requirements, reputable manufacturers like us offer highly customized **knotted fence** solutions. This goes beyond standard roll dimensions to include specific wire gauges, horizontal and vertical spacing tailored to particular animal types (e.g., tighter bottom spacing for sheep, wider for cattle), and specialized coatings for extreme environments.

For instance, a client requiring **fixed knot deer fence** for an estate bordering a national park might need heights exceeding 8 feet and specific wire gauges to withstand heavy snow loads. Similarly, a vineyard owner might prioritize specific wire spacing to allow for equipment passage while deterring smaller pests. Our engineering team works closely with clients to understand their exact needs, leveraging CAD tools and extensive material science knowledge to design and manufacture fence products that perfectly fit the application. This consultative approach ensures optimal performance and minimizes over-specification or under-performance.

Precision manufacturing for tailored **fixed knot fencing** designs.

The Meticulous Manufacturing Process of Knotted Fence

The production of a high-quality **knotted fence** involves a sophisticated, multi-stage manufacturing process that combines precision engineering with material science expertise. Our commitment to quality ensures every step adheres to the highest industry standards.

Imagine a highly automated, yet meticulously monitored, production line:

⚙️

1. Wire Rod Sourcing & Drawing:

The journey begins with high-quality steel wire rods, primarily high-carbon or low-carbon steel, selected for their tensile strength and ductility. These rods undergo a drawing process, where they are pulled through progressively smaller dies to achieve the precise wire gauge (diameter) required. This critical step significantly influences the final strength and resilience of the **knotted fence**.

🔬

2. Heat Treatment & Annealing:

To optimize the wire's mechanical properties, it often undergoes heat treatment, such as annealing. This process enhances ductility, making the wire more workable for the knotting process without compromising its eventual strength. Each batch of wire is subjected to rigorous material composition and tensile strength tests, complying with international standards like ASTM A641/A641M for zinc-coated steel wire.

🚿

3. Galvanization (Corrosion Protection):

Before knotting, the individual wires are meticulously cleaned (often acid pickled) and then hot-dip galvanized. This involves immersing the wire in molten zinc, creating a protective coating that bonds metallurgically with the steel. We predominantly use Class 3 galvanization for superior longevity, and for specific projects, advanced zinc-aluminum (Zn-Al) alloys are applied, offering up to 30 years or more of corrosion resistance, verified by salt spray tests conforming to ASTM B117 standards. This stage is crucial for the fence's lifespan, especially in challenging environments like coastal areas or those with fluctuating moisture levels, which directly relates to its application in industries such as petrochemical (where environmental resistance is critical for safety and longevity) and give-drainage (where constant moisture exposure can lead to rapid corrosion if not properly protected).

Automated machinery performing the precise knotting process for **knotted fence**.

🔗

4. Fixed Knotting:

This is the defining stage for **fixed knot fence**. Specialized high-speed machinery precisely weaves and ties the horizontal (line) and vertical (stay) wires together using a separate piece of wire to form a secure, non-slip fixed knot. Unlike hinge-joint fences, the fixed knot prevents vertical wires from sliding along the horizontal wires, creating a rigid and strong mesh that maintains its shape even under pressure. This innovative design significantly enhances the fence's ability to absorb impact and resist sagging, making it ideal for high-pressure applications like **high tensile fixed knot wire fencing for cattle**.

📏

5. Roll Forming & Tensioning:

As the fence fabric is created, it is simultaneously spooled into standard roll lengths (e.g., 330 ft or 660 ft). During this process, consistent tension is applied to ensure uniform mesh size and to prepare the fence for optimal performance during installation. The finished product adheres to dimensional accuracy specifications outlined in ISO 2235:1973 for wire netting.

✅

6. Quality Control & Inspection:

Each roll of **knotted fence** undergoes rigorous quality checks. This includes visual inspection for defects, measurement of wire gauges, knot integrity tests (pull-out strength), zinc coating thickness verification using magnetic induction or X-ray fluorescence, and dimensional accuracy checks. Compliance with ISO 9001:2015 ensures that our quality management system is robust and consistently delivers products meeting the highest standards. Our internal testing protocols often exceed minimum industry benchmarks to guarantee superior performance and a long usage life, typically 20-50 years depending on the coating type and environmental conditions. This rigorous testing ensures product reliability in diverse applications, from intensive agricultural use to critical infrastructure like petrochemical and metallurgical sites where component failure is not an option.

Thorough quality control checks ensure the durability and reliability of every **knotted fence** roll.

Application Cases: Knotted Fence in Action

Our commitment to delivering superior **knotted fence** solutions is best demonstrated through real-world applications and client success stories.

Client Feedback & Success Stories:

-

Large-Scale Ranch (Texas, USA): A prominent cattle ranch implemented over 50 miles of our **high tensile fixed knot wire fencing for cattle**. The client reported a significant reduction in fence repair costs (estimated 40% reduction annually) and improved herd management efficiency due to the fence's superior tautness and durability, even in varied terrain. "The fixed knot system is a game-changer for large properties; fewer posts, less maintenance, and absolute peace of mind," remarked the ranch manager.

-

Vineyard Protection (Napa Valley, CA): A premium vineyard adopted our 72-inch **fixed knot deer fence** to protect newly planted vines from deer damage. Within one season, they observed a near 100% elimination of deer-related crop loss in the fenced areas, directly impacting their yield and profitability. The fence seamlessly integrated with their existing vineyard aesthetic, offering both protection and discreet appearance.

-

Wildlife Sanctuary (Pacific Northwest, USA): Our customized 96-inch tall **fixed knot deer fence** with a tight bottom weave was utilized to delineate safe zones and restrict animal movement within a wildlife rehabilitation sanctuary. The non-abrasive knots ensured animal safety while providing robust containment, proving invaluable for their conservation efforts.

These cases exemplify how investing in high-quality **knotted fence** provides tangible returns in terms of security, operational efficiency, and long-term cost savings.

Robust **knotted fence** effectively securing a vast agricultural landscape.

Trust and Reliability: Our Commitment to You

At TY Wire Mesh, trustworthiness is at the core of our operations. We stand by the quality and performance of our **knotted fence** products through transparent policies and dedicated support.

Delivery & Logistics:

We understand the importance of timely delivery for your project timelines. Our typical delivery lead time for standard **knotted fence** orders is 2-4 weeks, depending on order size and destination. For large-scale or custom orders, we provide detailed production and shipping schedules upfront. We partner with reliable logistics providers to ensure your fence materials arrive safely and on schedule, whether by sea, land, or air freight, managing all necessary documentation and customs procedures for international clients.

Quality Assurance & Warranty:

Every roll of **knotted fence** is manufactured under strict ISO 9001:2015 certified quality management systems. We offer a comprehensive 20-year limited warranty on our fixed knot fencing, covering defects in materials and workmanship, and premature corrosion for Class 3 galvanized products. This commitment underscores our confidence in the longevity and performance of our products, far exceeding typical industry benchmarks.

Customer Support:

Our dedicated customer support team is available from 8 AM to 5 PM (GMT+8), Monday to Friday, to assist with product inquiries, technical specifications, order tracking, and any post-sales support. We provide detailed installation guides and offer expert advice to ensure your **knotted fence** project is a success from planning to completion.

Professional FAQ: Your Knotted Fence Inquiries Answered

What is high tensile wire, and why is it preferred for knotted fence?

High tensile wire is steel wire that has undergone specific drawing and heat treatment processes to achieve significantly higher breaking strength compared to traditional mild steel wire. It is preferred for **knotted fence** because it allows for longer spans between posts (reducing material and labor costs), maintains tension better over time, and can absorb greater impact from animals or environmental stresses without deforming, thus enhancing overall fence durability and longevity. This contributes to better long-term cost-efficiency.

What is the difference between a fixed knot and a hinge joint knot?

The key difference lies in rigidity and performance. A hinge joint knot allows the vertical wire to pivot around the horizontal wire, giving the fence some flexibility but making it prone to sagging and less resistant to animal pressure. A **fixed knot**, on the other hand, securely locks the vertical and horizontal wires together using a separate piece of wire, creating a rigid and non-slip structure. This rigidity provides superior strength, prevents sagging, and helps the fence maintain its shape even under heavy impact, making it ideal for containing active livestock like cattle or deterring wildlife.

How long does Class 3 galvanized knotted fence typically last?

Class 3 galvanized **knotted fence**, with its significantly thicker zinc coating (at least 2.4 oz/sq ft), typically lasts 20 to 40 years, and often even longer in arid climates. This contrasts sharply with Class 1 galvanization, which usually has a lifespan of 7-12 years. The extended durability of Class 3 makes it a more cost-effective choice over the long term, especially in corrosive environments or for critical infrastructure.

Can knotted fence be used for wildlife exclusion, specifically deer?

Absolutely. **Fixed knot deer fence** is a highly effective solution for wildlife exclusion. Fences designed for deer typically have a height of 7 to 8 feet (84 to 96 inches) and often feature graduated mesh spacing with tighter weaves at the bottom to deter smaller animals, while the overall robust fixed knot structure prevents deer from pushing through or climbing over. The lack of sharp points also makes it safer for wildlife that might come into contact with it.

What are the typical post spacing recommendations for high tensile knotted fence?

One of the significant advantages of high tensile **knotted fence** is the ability to use wider post spacing. While traditional fences might require posts every 8-12 feet, high tensile fixed knot fences can often be installed with posts spaced 20-30 feet apart, and sometimes even up to 50 feet on level terrain with appropriate bracing. This dramatically reduces the number of posts, labor, and overall installation costs, contributing to the fence's superior cost-effectiveness.

Is knotted fence suitable for all types of terrain?

Yes, the inherent flexibility and robust nature of **knotted fence** make it highly adaptable to various terrains, including undulating and hilly landscapes. Unlike rigid panel fences, it can follow the contours of the ground more effectively. The fixed knot design ensures the fence fabric remains stable and taut even when stretched over uneven surfaces, minimizing gaps and maintaining consistent strength across the fence line. Proper corner and end bracing are crucial for optimal performance on challenging terrain.

What are the relevant industry standards for knotted fence quality?

Key industry standards for **knotted fence** typically include ASTM A116 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire), ASTM A641/A641M (Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire), and sometimes ASTM A740 (Standard Specification for Hardware Cloth (Woven or Welded Wire Fabric Galvanized After Weaving or Welding)). For quality management systems, ISO 9001:2015 is the globally recognized standard. Adherence to these standards ensures consistent product quality, material integrity, and reliable performance over the fence's lifespan.

Further Reading & Industry Insights

For those seeking deeper knowledge on advanced fencing solutions and industry trends, we recommend exploring the following authoritative resources: