Exploring the Durable World of SS Mesh A Comprehensive Guide

SS Mesh, often referred to as stainless steel mesh, is a versatile product used in a wide array of industries due to its durability, corrosion resistance, and versatility. This article delves into the intricate aspects of SS mesh, exploring its applications, benefits, and the factors that make it a product of choice in numerous fields.

Starting with its material composition, SS mesh is manufactured primarily from stainless steel wires. Stainless steel itself is an alloy made up of iron, carbon, and a minimum of 10.5% chromium, which provides the coveted corrosion resistance. The grade of stainless steel used in the mesh determines its application, with grades like 304 and 316 being the most common due to their balance of affordability and performance.

The manufacturing process involves weaving or welding the stainless steel wires into a mesh. The weaving process results in different patterns such as plain, twill, or Dutch weave. Each weave type offers unique properties; for instance, plain weave is known for its precision and uniformity, making it suitable for applications requiring straightforward filtration. On the other hand, a twill weave allows the use of thicker wires, providing increased strength, while a Dutch weave combines different wire diameters for enhanced filtration capabilities.

One of the primary benefits of SS mesh is its exceptional durability. Stainless steel, by its nature, resists rust and oxidation, which makes the mesh ideal for use in harsh environments. This durability translates into a longer lifespan and reduces the need for frequent replacements, making it a cost-effective solution over time. Additionally, SS mesh maintains its structural integrity under high temperatures and pressure, broadening its application in industrial scenarios.

In terms of applications,

SS mesh's benefits are far-reaching. In the industrial sector, it's commonly employed for filtration purposes. For example, in chemical processing plants, SS mesh filters play a crucial role in removing impurities from various solutions and gases, thereby ensuring product purity and plant safety. Its resistance to chemicals and thermal properties make it indispensable in such settings.

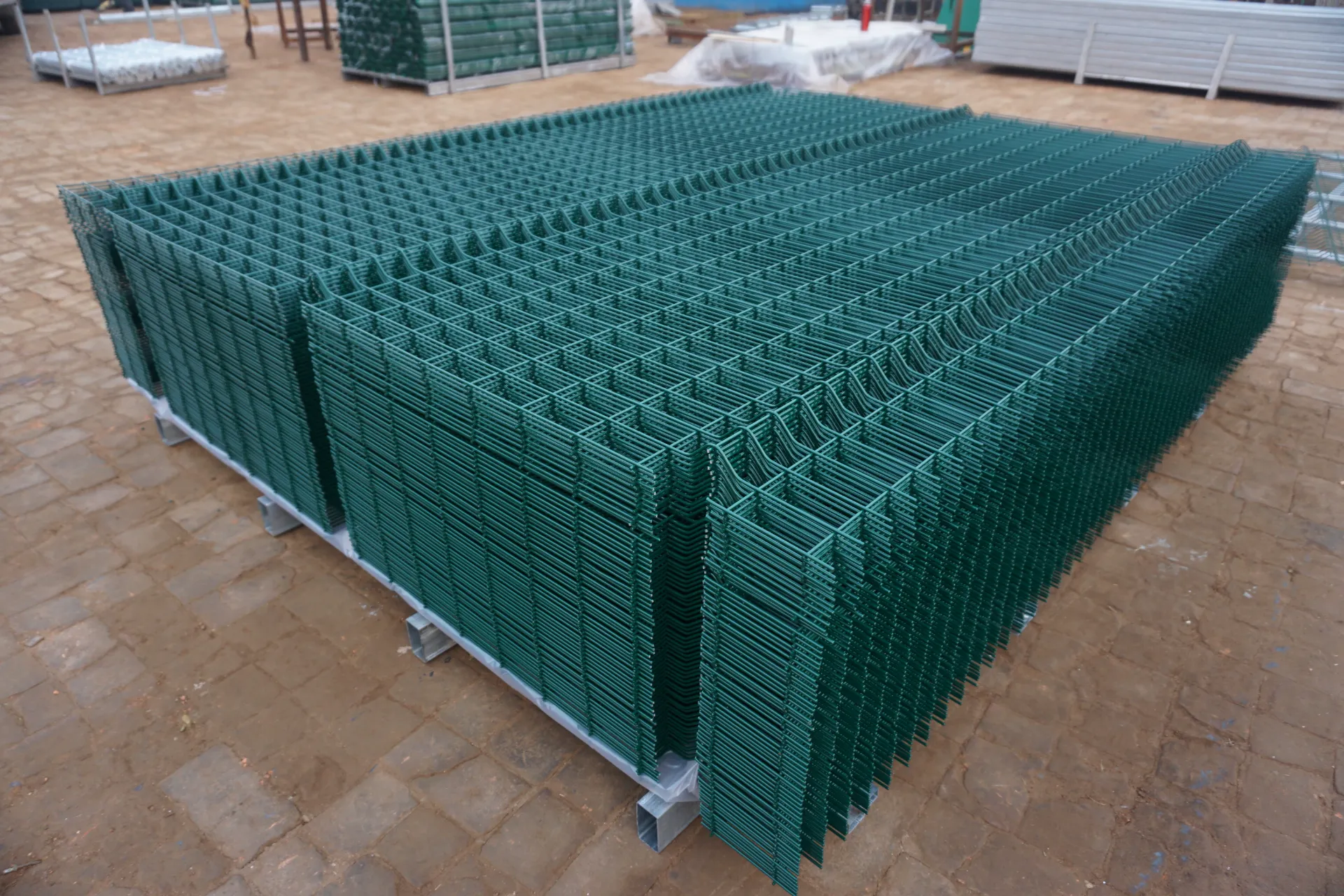

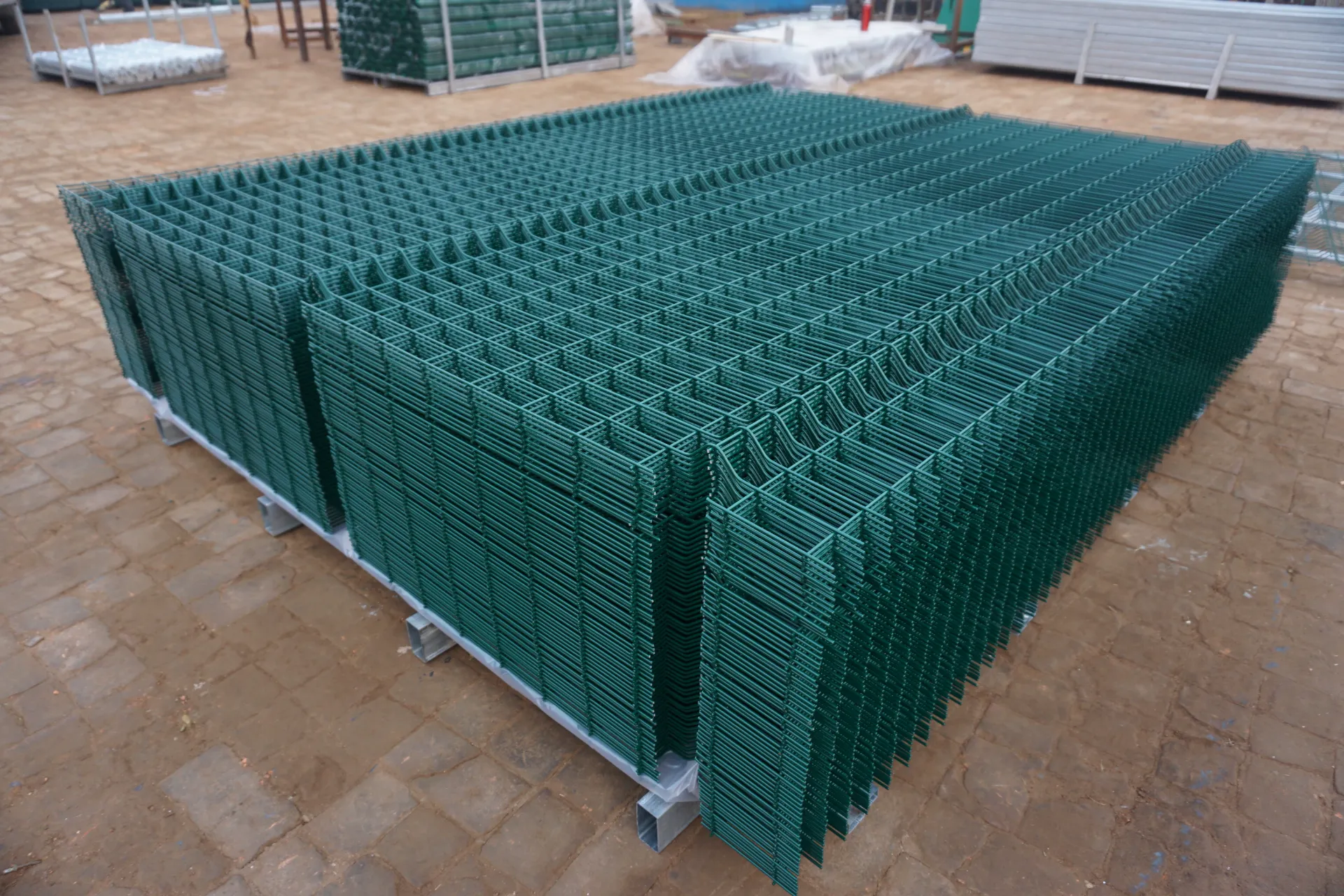

ss mesh

In the architectural realm, SS mesh adds an aesthetic and functional dimension to design. Architects favor it not only for its sleek, contemporary appearance but also for its ability to serve as a security measure in the form of protective screens or fences. Its use in building facades is gaining popularity for the same reasons; it provides a modern, professional look while offering ventilation and shade.

In the food and beverage industry, hygiene is paramount, and SS mesh is a staple for this reason alone. The material's surface is non-reactive, meaning it won't affect the taste of food and beverages. Moreover, it is easy to clean and sanitize, mitigating the risk of contamination – a critical factor in maintaining the highest health standards.

For those in the marine sector, the challenges posed by saltwater can lead to the rapid degradation of materials. Here, SS mesh stands out due to its anti-corrosive properties. Whether used as part of fishing equipment, boat components, or offshore installations, the mesh remains robust and reliable amidst constant exposure to salt and moisture.

When selecting the appropriate SS mesh for a project, several considerations should be factored in. The mesh size, which dictates the diameter of the openings, is crucial depending on whether the need is for filtration or security. The choice between welded or woven mesh will also hinge on the specific requirements; welded mesh tends to provide higher rigidity while woven mesh offers precision and flexibility.

Furthermore, understanding the environmental conditions and mechanical stresses the mesh will undergo ensures the selection of an appropriate stainless-steel grade. For instance, environments that are especially corrosive might necessitate the use of higher-grade stainless steel, like 316, which has molybdenum to enhance corrosion resistance.

In conclusion, SS mesh is a product that embodies the principles of versatility, durability, and efficiency. Whether employed in protecting delicate machinery in processing plants, enhancing the visual and functional aspects of modern architecture, assuring quality in food production, or withstanding harsh marine conditions, its applications are as diverse as they are essential. As industries continue to push the boundaries of what's possible, the demand for reliable, high-performance materials like SS mesh will undoubtedly rise, cementing its importance in both traditional and innovative ventures. The expertise involved in selecting and utilizing SS mesh effectively supports its standing as a critical component in today's industrial and commercial landscapes.

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language