TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

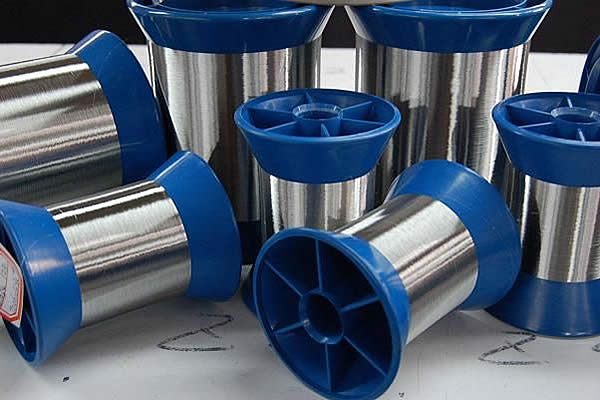

Coated Iron Wire An Overview of Its Applications and Benefits

Coated iron wire, often referred to as galvanized wire or vinyl-coated wire, has become a staple material across various industries due to its durability and versatility. Iron wire is coated with materials like zinc or plastic to enhance its resistance to corrosion, making it an optimal choice for both indoor and outdoor applications. This article delves into the properties, applications, and benefits of coated iron wire.

Properties of Coated Iron Wire

The primary advantage of coated iron wire is its enhanced resistance to environmental factors. The coating provides a protective barrier that prevents rust and corrosion, extending the wire's lifespan significantly compared to uncoated iron wire. For instance, galvanized iron wire, which is coated with zinc, can resist corrosion for years, even in harsh weather conditions. On the other hand, vinyl-coated wire offers additional protection, as the plastic layer not only safeguards against moisture but also provides a degree of insulation, reducing conductivity.

Moreover, coated iron wire is available in various diameters and tensile strengths, making it suitable for a wide range of applications. It can be easily cut, bent, and shaped to meet specific project requirements, making it a highly adaptable material.

Applications of Coated Iron Wire

Coated iron wire is used in numerous fields, from agriculture to construction. In agriculture, it serves as a fencing material, providing secure enclosures for livestock and protecting crops from wildlife. The corrosion resistance of coated wire ensures that fences remain intact for longer periods, even when exposed to outdoor elements.

In construction, coated iron wire is used for reinforcing concrete structures, creating wire meshes for various applications, and binding materials together

. It’s essential in both residential and commercial buildings, enhancing structural integrity while being cost-effective.

The crafting and decoration industries also utilize coated iron wire. Artists and DIY enthusiasts appreciate its versatility, using it to create intricate designs, sculptures, and decorative elements. The coating allows for aesthetic customization, as it comes in various colors that can match any design theme.

Additionally, coated iron wire plays a critical role in manufacturing. It is widely used in the production of goods such as hangers, mesh storage solutions, and garden trellises. Its strength and flexibility make it ideal for products that require a solid but workable material.

Benefits of Using Coated Iron Wire

One of the most significant benefits of coated iron wire is its longevity. The protective layers prevent oxidation, which is a common issue with traditional iron. This durability translates to lower maintenance costs and fewer replacements, making it a cost-effective choice over time.

Another advantage is its environmental resilience. Coated iron wire can withstand extreme temperatures, humidity, and exposure to chemicals, making it suitable for diverse environments. This feature also means that it can maintain its integrity and appearance over prolonged periods, making it an ideal choice for outdoor projects.

Finally, the versatility of coated iron wire allows it to be tailored for specific applications. Whether it’s for fence construction, artistic endeavors, or industrial uses, the availability of different coatings and diameters means that there is a coated iron wire solution for virtually every need.

Conclusion

Coated iron wire is an exceptional material that has found its place in a multitude of industries due to its strength, corrosion resistance, and flexibility. Its applications range from agricultural fencing to construction reinforcement, art, and manufacturing. By choosing coated iron wire, individuals and businesses benefit from durability, cost-effectiveness, and versatility, making it a smart investment for a wide array of projects. As technology advances, we can expect further enhancements in the quality and applications of coated iron wire, solidifying its importance in modern industry and everyday use.