Gabion Basket Retaining Walls: Industry Trends, Technical Comparison & Best Practices

Gabion basket retaining wall systems – also referred to as gabion wall, gabion wall baskets, and gabion retaining wall – are a cornerstone of modern geotechnical engineering. Used globally for civil, landscaping, and infrastructure projects, these modular wire mesh cages filled with stone offer sustainable, high-performance solutions for earth retention, erosion control, and architectural design.

1. Industry Insights & Market Analysis

The gabion basket retaining wall market is valued at USD 1.35 billion in 2023 and is expected to register a CAGR of 6.9% through 2028, according to industry research. This rise is driven by:

- Infrastructure upgrades & flood control in Asia, Middle East, Europe (road, rail, waterway projects)

- Green building initiatives seeking erosion-resistant, permeable retaining solutions

- Increased adoption in landscaping, mining, petrochemical, and water management sectors

2. Gabion Basket Retaining Wall: Product Overview

The gabion basket retaining wall comprises precision-engineered steel wire mesh cages, factory filled or on-site filled with graded natural stone. Engineered for modular deployment, these gabion wall baskets integrate seamlessly into challenging terrain, offer free-draining structures, and—by their flexible mass—mitigate hydrostatic pressure and accommodate subsidence:

| Parameter |

Standard Value |

Industry Range |

Notes / Standards |

| Mesh Opening |

60x80mm, 80x100mm, 100x120mm |

60-120mm |

EN 10223, ASTM A975/A975M |

| Wire Diameter |

2.7mm, 3.0mm, 3.5mm, 4.0mm |

2.7mm - 4.5mm |

EN 10244-2, ISO 9001 |

| Galvanization |

Zn ≥ 240g/m² |

180-275g/m² |

ISO 10684 |

| Coating |

PVC or Zn-Al Alloy (Galfan) |

PVC, PA6, PE |

ASTM A975, TB/T 3272-2005 |

| Basket Size |

2x1x1m, 3x1x1m, custom |

1x1x1m to 6x2x2m |

Customizable |

| Service Life |

> 50 years |

25-80 years |

Salt spray test, ISO 9227 |

| Shear Strength |

≥ 30 kN/m² |

20-60 kN/m² |

EN ISO 10319 |

| Applicable Standards |

ASTM, ISO, CE, ANSI |

GB, EN, etc. |

Project-based |

3. Manufacturing Process of Gabion Basket Retaining Wall

Raw Material Selection:

Only high-tensile, low-carbon steel wire (typically Grade Q195/Q235) is used, with chemical composition and tensile strength monitored per ISO 16120.

→

Wire Drawing & Annealing:

The steel wires are drawn to precision diameters under tight tolerance (±0.05mm), then annealed to improve ductility and prevent fracture during weaving.

→

Surface Coating:

Advanced galvanization or Galfan (Zn-5%Al) alloy coating is applied by hot-dip process (ASTM A641/A856), with optional PVC hot fusion for corrosion-proofing.

→

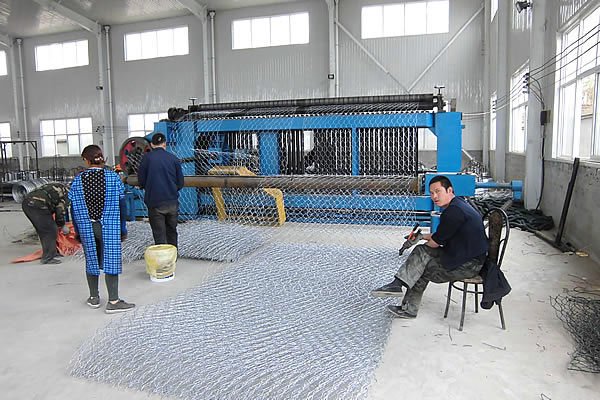

Mesh Weaving:

Hexagonal double twisted weaving (per EN 10223-3) on CNC automated lines ensures optimal resistance to unraveling and accurate dimensional repeatability.

→

Cutting, Forming, & Assembly:

Mesh is cut and bent to form baskets; selvedge wires are reinforced and lacing hooks/staples applied at joints for enhanced stability.

→

Quality Control:

Testing according to ISO 9001, including mesh opening dimension, tensile, coating quality, and anti-corrosion salt spray tests (ISO 9227).

Note: Each step is critical to lifecycle integrity, especially for applications in petrochemical and water engineering where corrosion resistance is paramount.

4. Gabion Wall Manufacturer Comparison (2024 Update)

Selecting a trusted gabion wall manufacturer is vital for ensuring compliance, structural longevity, and tailored service. Below is a comparative matrix of leading suppliers:

| Vendor |

Production Capacity |

Main Materials |

Certifications |

Lead Time * |

OEM Offered |

| TY Wire Mesh (official) |

14,000 tons/yr |

Galvanized & Galfan mesh, PVC/PE coated |

ISO 9001/14001, CE, ASTM |

7-18 days |

Yes |

| Geobrugg AG |

9,600 tons/yr |

Galfan, Stainless steel (AISI304) |

ISO 9001, EN/CE |

20-28 days |

Partial |

| Maccaferri |

28,000 tons/yr |

Zn/Al mesh, PA6-coated |

CE, ISO 14001 |

12-22 days |

Yes |

| Tiansheng Gabion |

8,200 tons/yr |

Galvanized, PVC-coated |

ASTM, ISO 9001 |

18-30 days |

Partial |

* Lead time from order confirmation to FOB delivery (subject to project volume and customization).

5. Customization, Technical Advantages & Application Expansion

- Modular Flexibility: Units are customizable by length, width, height (500mm to 2000mm tall, any length), and mesh aperture—ideal for projects with varying hydraulic, seismic, or soil load demands.

- Durability & Life: Anti-rust lifespan surpasses 50 years under normal conditions; Galfan/PVC options extend this in saline or polluted environments.

- Green Solution: Open mesh permits vegetation growth, encourages aquifer recharge, reduces surface run-off, and supports biodiversity (as validated by US EPA studies).

- Rapid Installation: No on-site welding required. On-site filling allows real-time adjustment to settlement, with labor-cost savings up to 30% vs. concrete.

- Testing Data: Shear resistance and load tests per EN ISO 10319 and local codes confirm anti-slip, anti-topple performance even in seismic zones.

6. Gabion Retaining Wall Application Scenarios and Case Analysis

Case 1: Petrochemical Coastal Plant Revetment (Saudi Arabia, 2022)

- Challenge: Severe saline corrosion, tidal hydraulic pressure, and requirement for no-maintenance structure.

- Solution: 3-layer gabion basket retaining wall, Galfan mesh, PVC coating, 2.7mm wire, filled with basalt. Total length: 920m, max height: 5.5m.

- Results: Lab-verified corrosion rate < 0.21mm/year. No settlement or mesh breakage after two typhoon seasons, per owner feedback.

Case 2: Highway Slope Stabilization (Germany, 2021)

- Challenge: Steep slope, risk of landslide after heavy rainfall, need for eco-friendly structure to allow vegetation growth.

- Solution: Custom gabion wall baskets (80x100mm mesh, 3.0mm Galfan/PVC), installation in staged lifts, geotextile interface, local river stone.

- Impact: >8,000 m² stabilized, observed zero surface flow & no erosion (verified by annual geotechnical inspection).

Case 3: River Bank Restoration (USA, 2020)

- Scope: 1.7km gabion retaining wall network for urban flood control.

- Special Features: Mix of 2x1x1m and 3x1x1m cages, filled with granite, layered for step stability. Integrated with native plant seeding.

- Outcome: Flood event in 2022: all cages intact, no collapse. Vegetative cover reached >75% by year two.

7. Frequently Asked Questions: Gabion Wall Baskets & Best Practices

Professional FAQ

1. What material standards do gabion wall cages conform to?

Gabion wall cages are constructed from high-tensile steel wire conforming to ASTM A975, EN 10223, and ISO 16120, ensuring strength, ductility, and consistent mesh opening.

2. What mesh size and wire diameter is recommended for heavy-duty retaining walls?

Standard mesh openings are 80x100mm or 100x120mm combined with wire thicknesses of 3.0mm to 4.0mm, giving optimal rigidity and anti-unraveling performance.

3. How is corrosion resistance achieved in gabion basket retaining walls?

Dual protection: galvanization (Zn ≥ 240g/m², ISO 10684) plus optional PVC or Galfan coatings (Zn-Al alloy) extend service life in aggressive environments. Salt spray tests per ISO 9227 validate performance.

4. How do gabion retaining walls behave in seismic zones or on uneven ground?

Their flexible modularity allows settlement without cracking—ideal for seismic areas. Internal stone infill disperses loads and absorbs displacement energy, per

peer-reviewed studies.

5. What is the typical service life and warranty?

Service life is generally > 50 years (tested by accelerated weathering, EN ISO 9223). Manufacturer warranty is 10-20 years against manufacturing defects or premature corrosion.

6. Can gabion wall baskets be installed in cold or saline coastal environments?

Yes—Galfan and PVC-coated gabion wall cages are resistant to both chlorides and frost, recommended for coastline, harbor, and bridge embankments.

7. What quality assurance and post-sales support is provided?

Leading vendors deliver full EN/ISO certification, routine third-party inspection, and technical support from design to installation, including 24/7 engineer hotline and rapid replacement of any shipment defects.

8. Delivery, Warranty, and Customer Support

- Lead Time: 7-21 days ex works, tailored to quantity and customization level.

- Warranty: 10-20 years against structural failure/corrosion (see contract).

- Support: Free technical design assistance, 3D layout drawings, on-site engineer support (by request), 24h response service.

- Certifications: All gabion baskets ship with ISO/CE/ASTM compliance documents and pass pre-shipment testing (full records provided).

9. Data Visualization: Gabion Basket Retaining Wall Parameter Trends

10. Conclusion & Industry References

With robust third-party certifications, eco-friendly advantages, and flexible performance in the harshest geotechnical environments,

gabion basket retaining wall technology remains the benchmark for sustainable infrastructure. For detailed project solutions or to request

gabion wall baskets tailored to your site, consult certified manufacturers or see our product page:

gabion basket retaining wall.

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language