TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

The Advantages of Coated Stainless Steel Wire Rope

When it comes to lifting, rigging, and construction applications, the choice of materials is crucial for ensuring safety, durability, and efficiency. One such innovative solution that has gained popularity in various industries is coated stainless steel wire rope. This versatile and reliable product offers numerous benefits that make it an ideal choice for a wide range of applications. In this article, we’ll delve into the properties, advantages, and applications of coated stainless steel wire rope, illustrating why it has become a preferred material in many sectors.

Understanding Coated Stainless Steel Wire Rope

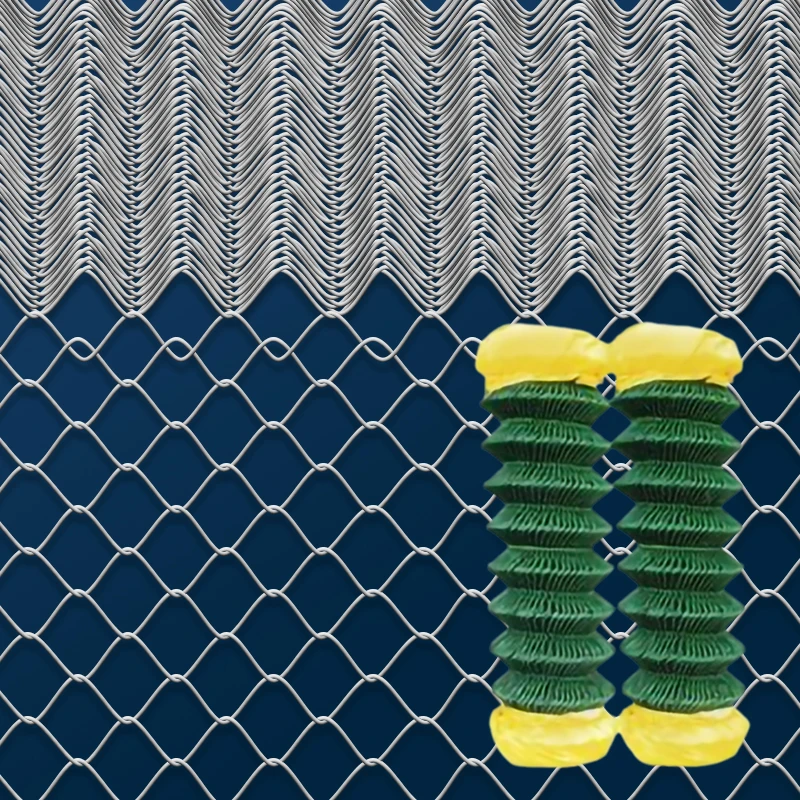

Coated stainless steel wire rope consists of stainless steel strands that are often coated with a protective layer, typically made of plastic materials such as nylon, polyurethane, or PVC. This coating serves multiple purposes, enhancing the performance and longevity of the wire rope. The stainless steel core provides high tensile strength and resistance to corrosion, while the outer coating adds additional protection against wear, abrasion, and environmental factors.

Key Advantages

1. Corrosion Resistance One of the standout features of stainless steel wire rope is its inherent resistance to rust and corrosion. This property is particularly advantageous in environments exposed to moisture, chemicals, and varying temperatures. The addition of a coating further enhances its durability, making it an ideal choice for marine applications, construction sites, and industries where exposure to harsh conditions is a concern.

2. Improved Grip and Handling The coated surface of the wire rope improves its grip, making it easier to handle and manipulate. This is especially beneficial in lifting and rigging operations where control and precision are paramount. The coating can also reduce the likelihood of the rope slipping through pulleys or clamps, enhancing overall safety during use.

3. Reduced Friction The smooth, coated surface reduces friction during operation, which not only prolongs the life of the wire rope but also improves efficiency. This decrease in friction minimizes wear on both the wire rope and the equipment it interacts with, leading to lower maintenance costs over time.

4. Visibility Coated stainless steel wire ropes can be produced in various colors, making them highly visible, especially in construction and industrial environments. This visibility enhances safety by making it easier to spot the wire rope during operations, reducing the risk of accidents.

5. Versatility Coated stainless steel wire ropes can be customized to meet specific requirements, including varying diameters, strengths, and coatings. This versatility allows them to be used in numerous applications ranging from architectural installations to heavy-duty lifting equipment.

Applications

Coated stainless steel wire rope is utilized across multiple industries due to its remarkable properties. In the construction sector, it is often used for suspended loads, scaffolding, and rigging systems. The marine industry benefits from its corrosion resistance, using it for mooring ropes, anchoring systems, and in fishing equipment.

Additionally, the architectural field employs coated stainless steel wire ropes for decorative and structural applications, such as cable railings and tensioned systems. The aesthetic appeal and durability of these ropes make them suitable for both functional and decorative uses in buildings and bridges.

In the field of telecommunications, coated wire ropes are employed in the installation of antennas and cables. Their strength ensures that heavy equipment can be securely lifted and positioned. Furthermore, industries that deal with lifting heavy loads, such as construction and crane operations, rely on coated stainless steel wire rope for optimal performance and safety.

Conclusion

In summary, coated stainless steel wire rope stands out as a resilient and multipurpose material suitable for a variety of applications. Its combination of strength, corrosion resistance, improved handling, and versatility makes it a top choice across several industries. As technology and material science advance, we can expect further innovations in the development of coated stainless steel wire rope, ultimately enhancing safety and efficiency in diverse applications. Whether you operate in marine environments, construction, or design, adopting coated stainless steel wire rope can undoubtedly lead to improved performance and greater peace of mind.