Steel wire coated products have revolutionized industries ranging from construction to telecommunications, driven by their enhanced durability and performance. In this comprehensive exploration, we delve into the unmatched benefits of steel wire coated solutions, underscoring their importance, versatility, and the trust they've garnered across various sectors.

Steel wire coatings primarily serve the purpose of enhancing the inherent strength and longevity of steel wires. The coating materials, which typically include polymers like PVC (Polyvinyl Chloride), nylon, or a galvanizing layer, provide a protective barrier against environmental aggressors such as moisture, UV radiation, and corrosive substances. This layer significantly extends the wire's lifecycle, proving indispensable in settings exposed to harsh conditions.

From a professional standpoint, the expertise involved in selecting appropriate coatings is non-trivial. Engineers and material scientists meticulously analyze usage environments to recommend the most suitable coating to ensure optimum performance. For example, PVC-coated wires are favored in marine environments for their excellent resistance to saltwater, whereas nylon coatings are renowned for their abrasion resistance, utilized in settings that experience substantial physical wear and tear.

The authoritativeness of steel wire coated products is evidenced by their widespread application in critical infrastructure projects. In telecommunications, for instance, these wires are often employed in the construction of communication towers and antenna systems. The protective coatings not only shield the wires from environmental damage but also enhance signal integrity by minimizing interference caused by environmental factors.

In the realm of agriculture, steel wire coated products are extensively used in fencing applications. Farmers rely on these coated wires to create durable, weather-resistant enclosures that protect livestock from predators while withstanding the test of time against the elements. The dependability of these products has established them as a cornerstone in agricultural fencing solutions.

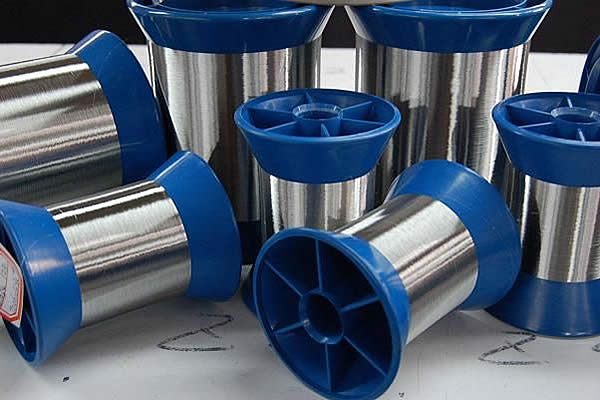

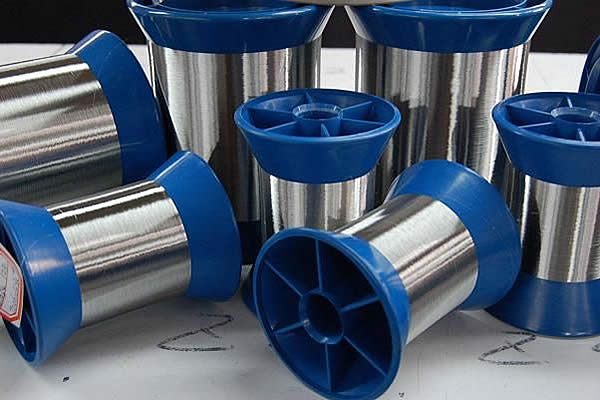

steel wire coated

The trust placed in steel wire coated products is built on a foundation of rigorous testing and quality assurance. Manufacturers conduct stringent assessments to ensure that coatings adhere uniformly and maintain their protective properties over extensive periods. Accredited laboratories often perform tests simulating extreme conditions to validate the performance claims of these coatings. The result is a product that stakeholders can rely on for both routine and mission-critical applications.

Innovation continues to drive the evolution of steel wire coatings. Recent advancements have introduced eco-friendly coatings that reduce environmental impact without compromising performance. These innovations align with the growing global emphasis on sustainability, offering stakeholders an opportunity to meet environmental compliance standards while benefiting from the robust protection these coatings provide.

Case studies further highlight the effectiveness of steel wire coated products. In a notable example, a solar energy company upgraded its infrastructure using PVC-coated wires, resulting in a significant increase in operational efficiency and a marked reduction in maintenance costs. This not only reinforced the cost-effectiveness of investing in quality coatings but also demonstrated a clear return on investment over time.

The global market for steel wire coated products continues to expand, driven by the growing demand across different sectors. Market insight reports predict a steady increase in consumption, spurred by urbanization and infrastructure development, particularly in emerging economies. This trend underscores the indispensable role these coated wires play in modern engineering and construction projects.

In essence, steel wire coated products represent a fusion of engineering expertise and innovative material science designed to meet the evolving needs of various industries. Their proven track record, bolstered by continuous advancements and stringent quality standards, ensures they remain a trusted component in critical applications worldwide. As industries face new challenges posed by environmental and operational demands, the role of steel wire coatings as a protective and enhancing measure will only grow stronger.

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language

TEL:

+86-13102802206

TEL:

+86-13102802206

Email:

fencenetting@china.com

Email:

fencenetting@china.com

Language

Language